Within the AxFlow Group we share our values and principles for sustainable business, shown through our group common pieces such as our Supplier Code of Conduct and our own Code of Ethics. We have also identified some key metrics that we measure across our group that together stipulates our minimum requiremetns on ourselves and our partners. When joining the AxFlow Group you are handed the foundation of these common values, principles, and routines, and can put all your focus on incorporating sustainability where it matters the most, the customer offer.

Our commitment to sustainability is not just a corporate responsibility but a natural extension of our core values of being good to work with, far-sighted, and making things happen. We seek to improve sustainability performance across our entire value chain, targeting the topics of people, climate and circularity

99 %

22

60 %

We are convinced that sustainability is a key stone in futureproofing not only ourselves, but also our customers and supplying partners. Our strong belief is that our single most important contribution is to enable our customers to find the most sustainable solution for the, whether it be designing an efficient processing system, replacing old equipment with more efficient ones, or renovating existing equipment.

By providing the most energy efficient solution to our customers when choosing equipment, we can help our customers reduce their energy consumption, CO2 emissions, and minimize waste occuring in their operations.

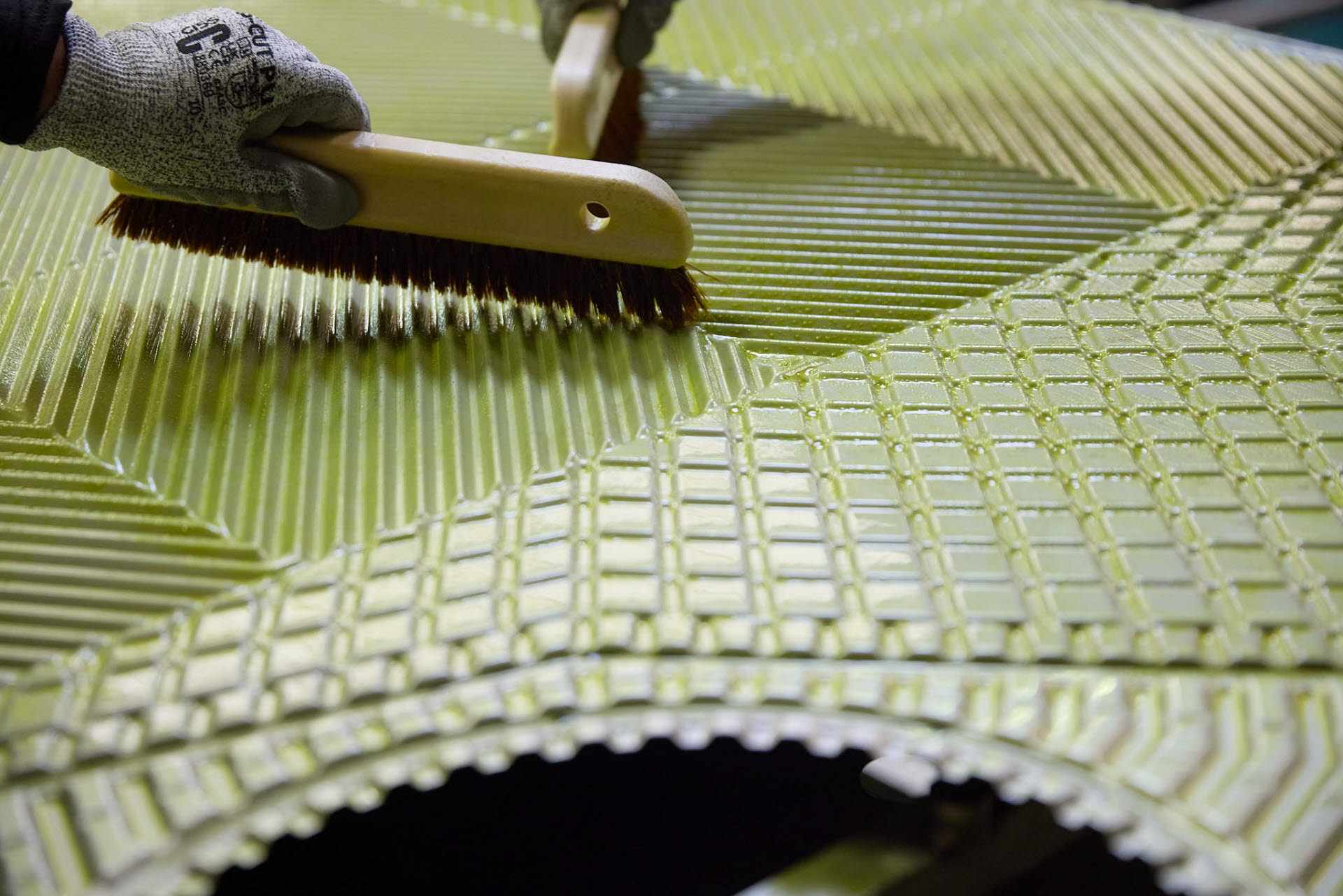

Our dedication to circularity is also strongly connected to our service offering, and how we can maintain, repair, renovate, and refurbish fluid handling equipment. A key pillar in our sustainability strategy is to increase our service capability in terms of type of fluid handling equipment, customer segments, and markets where we are available with our highly skilled service engineers.

This is also why we are so committed to people and being good to work with. To give our customers the best possible solution includes being an attractive employer, a commitment to diversity and inclusion, and always having a people development focus in our organisation.

A united effort for a greener future

AxFlow is committed to providing sustainable customer solutions, with a clear focus on reducing environmental impact — particularly through energy efficiency and minimizing waste. This commitment is driven by both strategic initiatives and local actions across the organization.

Our single most important contribution is that we can influence our customers to choose the most sustainable solution for them.

Hilda Molin Sustainability Manager, AxFlow