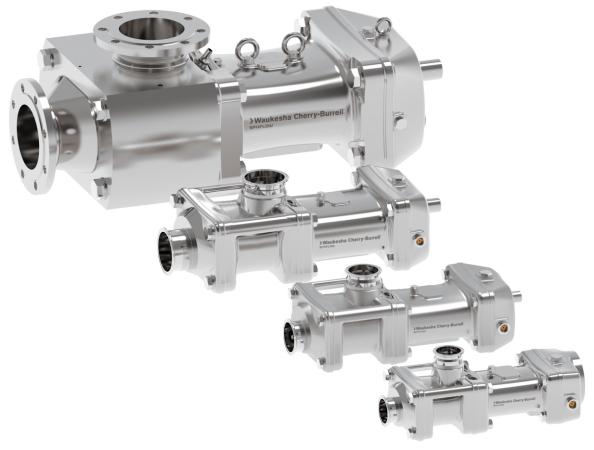

Waukesha Twin Screw pump

SubCategory: ScrewPumps

Manufacturer: WaukeshaCherryBurrell

Industry: BeautyPersonalCare;PaintSurfaceCoating;OilFatsMayonnaiseProduction;OilGas;BrewingBeverages;FoodBeverage;Pharmaceutical;PaintResinProduction;FruitConcentrateProduction;Chemical;Petrochemical;Distilleries;ConvenienceFood;Diary;BakeryConfectionery

Key specifications

- Flows up to 200 m³/h

- Pressure up to 30 bar

Product features

- Provides gentle and smooth pumping action.

- Pumps large particulates without degradation.

- Simple screw replacement without the need for screw shaft re-synchronization.

- Cartridge design enables quick and easy seal replacement.

- Operating pressure up to 16 - 25 bar (varies with pump size and design).

- Pumping of the most diverse products with a single pump.

- Yields outstanding results for both Steam in-Place (SIP) and CIP cleaning processes.

- Process flexibility - Low inlet pressure requirement and a wide range of operating speeds allow for multiple duties including process and CIP supply. Bi-directional flow capability without making modifications to the pump.

Description

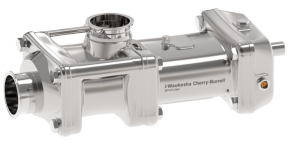

Functioning as both a product and Clean-in-Place (CIP) pump, this twin screw pump offers unparalleled versatility. Its cutting-edge technology simplifies the screw replacement process, eliminating the need for re-synchronizing the screw shafts. This hassle-free operation ensures minimal downtime and maximizes productivity.

The pump’s cartridge design enhances convenience by enabling swift and effortless seal replacement. With the self-centering flange housing, coupling alignment is easier, eliminating the need for realignment after service work. For additional user convenience, an optional close coupled motor adapter is available.

The WTS pump is available in two versions to cater to industry-specific requirements.

• The 3A authorized version: WTS 70, 104, 130

• The EHEDG certified version: WTS 70, 104, 130, 180