Three approaches can be taken when it comes to the basic pump design for fluids containing abrasives.

- To use a hard, wear-resistant material for the internal components such as PE or chrome.

- Reduce the velocity of the fluid in the pump chamber by using a low shear and slow pumping action .

- Use a soft material with tear resistant properties as found in hose pumps, AOD pumps and eccentric disc pumps.

At Axflow we can offer all of these solutions across the UK when it comes to pumping abrasive fluids.

All of our air diaphragm pumps are capable of handling liquids containing abrasives.

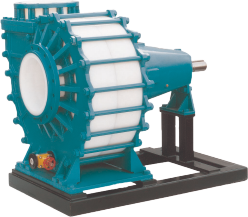

Waukesha rotary lobe and circumferential piston pumps are extremely good at passing liquids with abrasives in by using a gentle pumping action.

With the correct hose materials, AxFlow's range of Realax peristaltic pumps can handle abrasive liquids.

We have three main ranges of centrifugal pumps capable of handling solids:

- Warman: a wide range of vortex pumps that can withstand abrasive liquids.

- Wernert: chemically resistant pumps - many to iso 22858 that will handle abrasive and corrosive liquids.

- Argal who offer pumps made from FRP.