Our WaterCyclone Systems remove solids of Specific Gravity over 1.15 and 25 microns or above in size, for water used to lubricate the stern tube bearings and mechanical shaft seals. Supplying high quality water to the stern tube bearings and seals greatly improves the reliability and mean time bewteen failure.

FLEXIBLE CONFIGURATION

- WaterCyclone Systems use a double pass as standard but can be configured as single or triple depending upon the vessel's requirements.

- The Flow and Pressure of cleaned water delivered by each Water Conditioning System can be set to the required values specified by the seal and stern tube manufacturers by means of integral bypasses and return lines.

- Just about any flow rate and pressure can be accommodated.

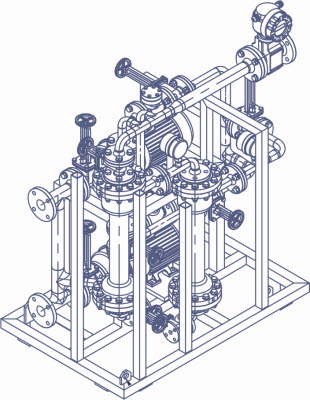

COMPACT AND EASY TO INSTALL

- WaterCyclone systems are constructed to allow entry through

- Pumps, cyclone separators, pipework, valves and control panels are supplied fully skid mounted and in a "Plug and Play" format for ease of installation.

MATERIALS OF CONSTRUCTION

- Systems for Seawater are manufactured as standard in Copper Nickel, Aluminium Bronze and High Alloy Duplex Steel.

- 316 Stainless Steel is available for "Closed Loop" systems or, for "Open Loop" Systems processing fresh water such as that found in inland waterways.

- Plastic construction is also available for installations where cost is a consideration and the system is not subject to such a rugged environment.

LLOYDS REGISTER

All WaterCyclone systems can be independently inspected and approved by Lloyds Register or any other appropriate certifying body.

AN EXPERIENCED SUPPLIER

WaterCyclone systems are used by stern tube manufacturers and on numerous retro fit projects around the world including naval vessels, ships on the Great Lakes, ore carriers and in Arctic and Antarctic waters.