supply & Install: water storeage tanks and mounted pumping system

Supply and install bespoke foul water storage tanks and surface mounted pumping system for the aviation industry.

Scope of works:

To design and install new foul water storage and pumping solutions to replace the existing old and troublesome system.

The concept of the design was based around non-intrusive works, easy access to equipment for maintenance and repair and minimal spares requirement (as all these systems only used 2 types of PD pump and 2 types of macerator/muncher)

All the pumping stations currently consist of a storage tank, 2 x submersible pumps, probe level control and control panel.

Considerations:

- Isolation, disconnection and removal of existing pumping stations

- Design around existing inlet, discharge and air vent pipework

- Design around available space for new tank and pumping equipment

- Design around future maintenance, removal and replacement of equipment

- Logistics of getting the components off site and onto site

- Routes via lifts, narrow corridors and door ways

- Over-pumping of existing services & impact to users

- Safety and wellbeing of other personnel around the work area

Some pumping stations to be replaced:

The client were looking at options to improve the current set up especially targeted at maintenance as this has been a constant issue.

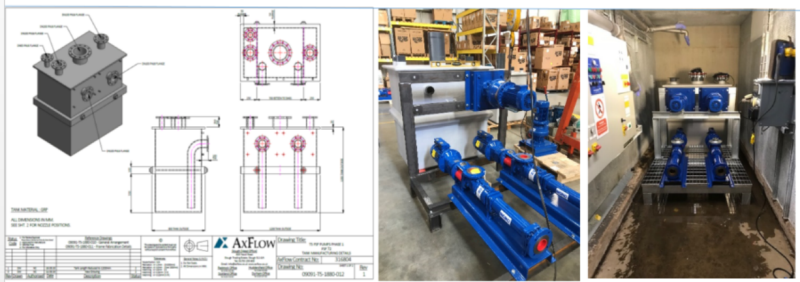

Axflow working with NOV (Mono) provided a solution that would help mitigate a lot of the problems by providing a new bespoke GRP sealed tank and utilising positive dospalcement pumps and macerators mounted externally of the tank. As no access to the tank was required other than for cleaning purposes, no hatches were provided only flanged connections with the largest connection having a suitable diameter to allow the use of puddle pumps for cleaning/overpumping if required.

Before old tank New tank & flanged New PD pumps New dual pump & controller connections & macerators macerator controller

New galvanised steel frames were manufactured to support the pumps and macerators independent of the tanks.

New tank drawing Frame being manufactured Frame positioned

In our workshop onsite

All works including design and installation were conducted by Axflow personnel