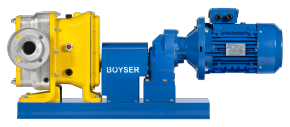

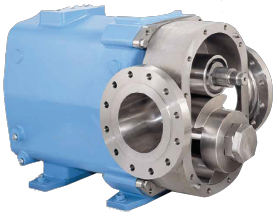

How rotary lobe pumps work

The lobes do not make contact being prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

- As the lobes come out of mesh, they create an expanding volume on the inlet side of the pump. Liquid flows into the cavity and is trapped by the lobes as they rotate.

- Liquid travels around the interior of the casing in the pockets between the lobes and the casing -- it does not pass between the lobes.

- Finally, the meshing of the lobes forces liquid through the outlet port under pressure.

Lobe pumps are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in lobe pumps than in other PD types. Since the lobes do not make contact, and clearances are not as close as in other PD pumps, this design handles low viscosity liquids with diminished performance. Loading characteristics are not as good as other designs, and suction ability is low. High-viscosity liquids require reduced speeds to achieve satisfactory performance. Reductions of 25% of rated speed and lower are common with high-viscosity liquids.