How to select gear pumps

There are a range of factors to consider when selecting Gear Pumps:

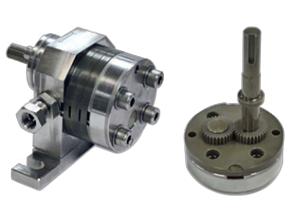

Flow rate –the amount of fluid to be transferred by the pump. The fluid is transferred through the clearances between the mating gears. The tight clearances between the gears are required for the effective displacement of the fluid.

Viscosity – resistance to the flow. The viscosity of the fluid plays a crucial in the role flow of the fluid. The fluids occupy the clearances between the gear and casing and are transferred. Low viscous fluids can be carried with ease, whereas high viscosity fluids need time to fill in the clearances, implying that the speed of the fluid must be decreased (the speed of the gears decreases with an increase in the fluid`s viscosity).

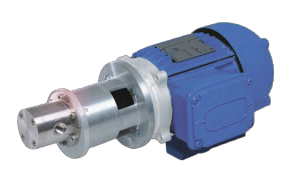

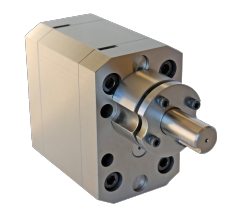

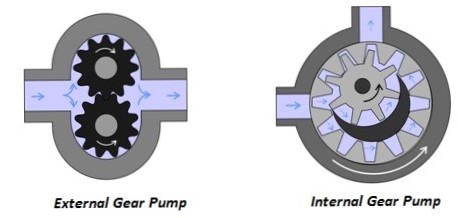

Internal or External – You must decide the type of pump required for our applications such as internal gear pump or external gear pump. External gears are most suitable for high-pressure and high-flow applications. Internal gear pumps are used in low-flow and precision flow applications.

Power – amount of energy required to move the fluid effectively in the required flow rate.