How to maintain vane pumps

How to maintain rotary vane pumps

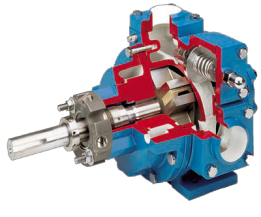

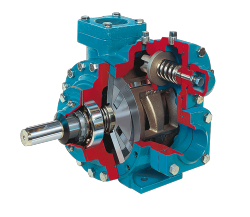

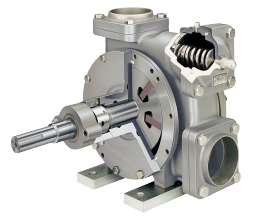

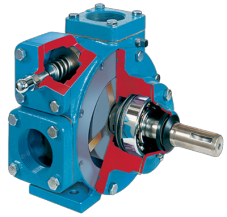

Rotary vane pumps are precision-engineered positive displacement pumps that deliver smooth, consistent flow for applications such as fuel transfer, lubrication, vacuum systems, and solvent handling.

While these pumps are known for reliability and long service life, their performance depends on routine inspection, proper lubrication, and timely replacement of wear components.

Routine Inspection and Performance Monitoring

Daily / Weekly Checks

-

Inspect for leaks around the housing, seals, and fittings.

-

Monitor noise and vibration levels — unusual sounds often indicate worn vanes, damaged bearings, or air ingress.

-

Check operating temperature: overheating can suggest poor lubrication or internal friction.

-

Observe pressure and flow rate: deviations from normal readings may signal vane wear or suction blockages.

Performance Tracking

Record flow, suction vacuum, and discharge pressure periodically to identify early performance drift.

A drop in vacuum or flow typically points to vane or liner wear.

Lubrication

-

Rotary vane pumps rely on either the pumped medium or a dedicated oil system for lubrication.

-

For lubricated pumps, check oil levels regularly and top up using manufacturer-approved oil grades.

-

Replace oil and filters per schedule (typically every 2,000–4,000 operating hours).

-

For dry-running or chemical-duty designs, ensure that the materials and coatings are compatible with the process fluid, as these pumps are more sensitive to frictional heat.

-

Avoid running the pump dry — this can rapidly damage vanes and the casing.

Vanes and Casing Maintenance

-

The vanes are the key wear components. They slide in and out of the rotor slots, maintaining tight contact with the casing to form the pumping chambers.

-

Over time, vanes wear down and lose sealing efficiency, reducing flow and vacuum performance.

-

Inspect vane length, surface condition, and edge sharpness during scheduled shutdowns.

-

Replace vanes when wear exceeds manufacturer limits or if visible scoring or chipping occurs.

-

Inspect the pump liner (cam ring) for scoring or corrosion and replace if the internal surface becomes rough or oval.

Bearings and Shaft Seals

-

Check bearings for wear, noise, or overheating. Replace if excessive play is detected.

-

Inspect shaft seals for leakage or product buildup.

-

Replace seals periodically — typically during major service intervals or whenever leakage exceeds acceptable limits.

-

Always use OEM seals designed for the pump’s operating pressure, speed, and fluid type.

Cleaning and Flushing

-

For pumps handling sticky, resinous, or viscous products, flush with a compatible cleaning fluid after use or before shutdown.

-

Operate at reduced speed during flushing to ensure proper cleaning without cavitation.

-

Never use incompatible solvents or abrasive cleaning agents that could damage internal coatings or elastomers.

Alignment and Drive Maintenance

-

Misalignment between the motor and pump shaft can cause vibration, noise, and accelerated bearing wear.

-

Check coupling alignment after installation or any maintenance involving the drive.

-

Inspect flexible couplings for cracks or fatigue and replace worn elements.

-

Verify that the pump is mounted on a stable, vibration-free base with proper alignment to the piping.

Storage and Standby Care

When not in operation:

-

Drain and clean the pump to prevent residue buildup.

-

Apply a light film of protective oil to internal surfaces to prevent corrosion.

-

Seal inlet and outlet ports to prevent dust or moisture ingress.

-

For long-term storage, rotate the pump shaft manually every few weeks to prevent vane sticking.

Preventive Maintenance Schedule

| Frequency | Maintenance Task |

|---|---|

| Daily / Weekly | Check oil level, pressure, and noise/vibration |

| Monthly | Inspect seals and monitor performance data |

| Quarterly | Change oil and clean filters |

| Annually | Inspect vanes, bearings, and liner; replace worn parts |

Following this schedule ensures reliable operation and minimizes unplanned downtime.