Fluid Handling Solutions for Paint and Surface Coating Applications

The paint and surface coating industry relies on precise fluid handling solutions to ensure accurate mixing, efficient application, and quality finishes. Throughout various stages, from raw material processing to final product application, tailored fluid handling equipment is essential to meet diverse requirements.

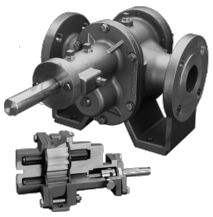

Pumps: Precision in Material Conveyance

Pumps play a vital role in conveying paint materials, ensuring consistent flow rates during mixing and application processes. Centrifugal pumps transfer paint materials within mixing and supply systems, while positive displacement pumps precisely move viscous paint compounds without altering their composition.

Valves: Control and Regulation

Valves provide precise control over paint flow, ensuring accuracy and preventing spillage or inconsistencies during the mixing and application phases. Ball valves regulate paint flow during mixing and distribution, while butterfly valves control paint movement within pipelines.

Vacuum Pumps: Assisting in Processing

Vacuum pumps contribute significantly to paint processing by aiding in eliminating air bubbles and degassing paint mixtures. Liquid ring vacuum pumps assist in the removal of air bubbles from paint mixtures, while rotary vane pumps contribute to paint degassing processes.

Heat Exchangers (HEX): Temperature Control

Heat exchanger (HEX) technology ensures precise temperature control in paint processing, enabling optimal consistency and quality in the final coating. Plate heat exchangers maintain consistent temperatures, while shell and tube heat exchangers regulate heating or cooling for specific paint formulations.

Mixers: Homogenization and Consistency

Mixers are essential for achieving consistent paint viscosity and color accuracy. They facilitate the thorough blending of paint ingredients, ensuring uniformity and quality in the final coating.

Why Choose AxFlow?

From conveying raw materials to ensuring proper mixing and application, these fluid handling solutions are tailored to meet the stringent requirements of the paint and surface coating industry, guaranteeing high-quality finishes and efficiency throughout the production and application processes.