Advantages of Axial Flow Pumps

- Axial flow pumps are high volume low head pumps.

- Axial flow pumps can be mounted horizontally or vertically

- As they are generally purpose made there are less limits on the materials they can be manufactured from.

Where to use Axial Flow pumps

Axial flow pumps tend to be utilised in applications which require rather high flow rates and a low amount of pressure. They can be used as circulating water pumps in power plants. As well as this, they’re commonly used in the chemical industry for circulating large amounts of fluids in evaporators. Whilst being useful in flood dewatering applications where substantial quantities of water need to be moved over a short distance, for instance over a levee or dyke. Marine applications include impounding pumps for docks and ports.

WHY BUY AXIAL FLOW PUMPS FROM AXFLOW

- AxFlow are the UK representatives for Gruppo Aturia, the oldest Italian pump manufacturer who offer a large range of axial flow pumps ranging from materials such as cast iron, stainless steel, bronze, duplex and super suplex stainless steel.

- Gruppo Aturia have supplied axial flow pumps to some of the world’s most prestigious projects including the MOSES scheme designed to stop Venice from flooding.

- AxFlow are experts at both the installation of axial flow pumps and their repair having carried out numerous projects in the maritime and land drainage sectors.

AxFlow GB provide stock available on a standard 2-3 days or express 24-hour delivery.

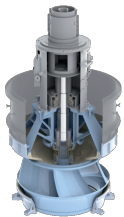

Axial flow pumps are a type of dynamic (centrifugal) pump that move fluid parallel to the pump shaft, rather than radially as in centrifugal pumps. They are designed for high-flow, low-head applications where large volumes of liquid must be transported efficiently — such as flood control, cooling water circulation, irrigation, and wastewater treatment.

In simple terms, they operate like a propeller in a pipe: the rotating impeller blades impart velocity directly along the flow axis, generating continuous movement of fluid.

Principle of Operation

-

Fluid Entry

The liquid enters the pump axially (in line with the shaft) through a suction bell or inlet guide. Flow is usually conditioned to be uniform and free of turbulence before reaching the impeller.

-

Impeller Action

The axial impeller—a propeller with several blades fixed to a hub—rotates at high speed. As the blades spin, they act like airfoils, creating a lift force that accelerates the fluid in the axial direction.

-

The lift generated by each blade depends on its angle of attack, curvature, and rotational speed.

-

Because the fluid motion is almost entirely parallel to the shaft, the pump develops velocity head rather than pressure head.

-

Energy Conversion

The kinetic energy imparted to the fluid by the impeller is partially converted into pressure energy by the discharge casing or diffuser vanes.

-

Discharge

The fluid exits axially through the discharge column or pipe. Diffuser vanes are often used to straighten the flow and recover additional pressure energy by decelerating the fluid efficiently.

How to Select an Axial Flow Pump

Selecting the correct axial flow pump requires balancing hydraulic performance, fluid characteristics, installation layout, and materials to ensure reliable, energy-efficient operation and long service life.

Define Hydraulic Requirements

- Flow rate (Q): Primary selection parameter. Accurately define required discharge flow to avoid oversizing and unnecessary energy consumption.

- Total Dynamic Head (TDH): Typically low (≈ 1–10 m per stage). Include static lift, friction, and minor losses. Select a pump operating near its Best Efficiency Point (BEP).

- NPSH: Ensure available NPSH exceeds required NPSH to prevent cavitation. Vertical or semi-submerged installations improve suction conditions.

Consider Fluid Properties

- Fluid type: Clean water, seawater, slurries, or effluents affect hydraulic design and materials.

- Temperature: Impacts bearing lubrication and thermal expansion.

- Solids content: Abrasive fluids require hardened impellers, wear coatings, or lined casings.

- Corrosiveness: Use stainless steel, duplex, bronze, or coated materials as required.

Select Installation Configuration

- Vertical pumps: Ideal for sumps and intake wells; space-saving and self-venting.

- Horizontal pumps: Suitable for limited headroom but require priming systems.

- Submersible or mixed-flow designs: Used for flood control, drainage, and variable water levels.

Evaluate Mechanical Design

- Impellers: Fixed-pitch (simple, robust) or adjustable-pitch (variable performance).

- Bearings: Water- or grease-lubricated, matched to service conditions.

- Drive options: Vertical motors, gear drives, or diesel engines.

- Column design: Modular sections sized to site depth and support requirements.

Efficiency and Control

- Select the pump with the highest efficiency at the duty point.

- Use adjustable-pitch impellers or VFDs for flow control while minimising throttling losses.

- Operating near BEP reduces vibration, wear, and lifecycle costs

Axial Flow Pump Maintenance Overview

Axial flow (propeller) pumps are used in high-flow, low-head applications such as flood control, cooling water circulation, and water transfer. Due to demanding hydraulic conditions, regular inspection and maintenance are essential to maintain efficiency and reliability.

Key Maintenance Practices

- Routine monitoring: Check for leaks, unusual vibration or noise, bearing temperatures, and changes in pressure, flow, or power consumption.

- Performance tracking: Record operating data and compare with baseline or factory test results to detect efficiency loss or wear.

- Bearings & lubrication: Ensure proper lubrication of line shaft and thrust bearings. Monitor oil condition, water flush flow, and bearing temperatures.

- Alignment: Verify shaft and motor alignment, particularly after installation or overhaul, to prevent vibration and premature wear.

- Impellers & columns: Inspect for erosion, corrosion, cavitation, or debris buildup. Maintain correct blade pitch and internal clearances.

- Seals & packing: Inspect mechanical seals or packed glands for leakage. Ensure correct materials and clean seal flush lines.

- Suction system: Keep strainers and suction bells clear and ensure adequate submergence to avoid cavitation and air entrainment.

Scheduled Overhaul & Storage

- Perform major inspections every 6–12 months, replacing worn bearings, seals, and wear components.

- For extended shutdowns, drain the pump, protect metal surfaces, store in dry conditions, and rotate the shaft periodically.

Hydraulic Characteristics

- Flow Direction: Parallel to the shaft (axial).

- Head Range: Typically 1–10 m per stage (can be higher with multi-stage designs).

- Flow Capacity: Very high — up to tens of thousands of cubic metres per hour.

- Efficiency: Excellent in high-volume, low-head service; often 80–90% hydraulic efficiency.

- Specific Speed: Very high (Ns > 10,000 in US units), meaning the pump is optimized for high flow, low head conditions.