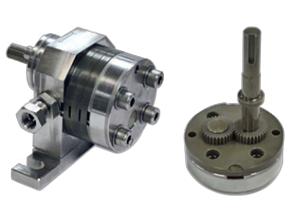

Why use External Gear Pumps? The external gear pump is the ultimate solution for high pressure pumping.

External Gear Pumps

13 series from 3 manufacturers

-

- Agriculture

- Aviation

- Beauty & Personal Care

- Building Services

- Ceramics

- Chemical

- Fish Farming

- Heating, Water & Sanitation

- Nuclear Power Plants

- Oil & Gas

- Paint & Surface Coating

- Paper Mills

- Petrochemical

- Pharmaceutical

- Power Generation

- Refineries

- Research & Development

- Surface Finishing

- Transportation

- Water Treatment

-

- Analysis

- Circulation

- Cleaning

- Control

- Desinfection

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Extraction

- Feed

- Filling

- Flow Control

- Greasing

- Handling

- Heating

- High-Pressure

- High-Temperature

- Injection

- Level Control

- Lift

- Lifting

- Low-Pressure

- Lubrication

- Medium-Pressure

- Metering

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Sampling

- Spraying

- Tempering

- Transfer

- Treatment

- Volumetric Dispensing

-

- Acetate

- Acids

- Alcohols

- Ammonia

- Caustic Solutions

- CIP Fluids

- Corrosive Dyes

- Corrosive Liquids

- Detergents

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Gels

- Glycol

- High Viscosity Liquids

- HydrochloricAcid

- Light Fluids

- Low NPSH

- Low Viscosity Liquids

- LPG

- Paints

- Personal Care Products

- Phosphoric Acid

- Silver Nitrate

- Solvents

- Sulphuric Acids

- Surfactants

- Thin Liquids

- Toluene

- Toxic Liquids

- Vegetable Oils

- Vinegar

- Viscous Liquids

- Water

- Water Hardness

-

- Adjustable-Flow

- Chemically Resistant

- Compact

- Containment

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Heavy-Duty

- High-Efficiency

- High-Performance

- Horizontal Mount

- Intrinsically Safe

- Low-Noise

- Magnetic Drive

- Mechanical

- Mechanical Seal

- Non-Metal

- Oil-Free

- Pulse-less

- Rotary

- Seal-less

- Self-priming

- Solids Handling

- Variable Speed

Do you need help finding the right pump that meets your needs?

We have experienced experts who are ready to help you!

Get in touch hereWhy buy external gear pumps from axflow

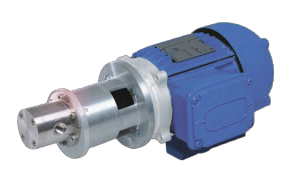

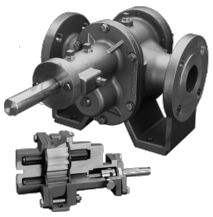

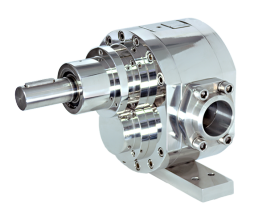

AxFlow supply external gear pumps from a range of different manufactures such as Slack & Parr, Pulsafeeder and Pompe Cucchi, enabling our customers to have a wide range of choices in order to ensure the optimum efficiency of your pumping applications.

Benefits of using external gear pumps

External gear pumps provide a range of benefits which prompt them to be useful in a variety of puimping applications.

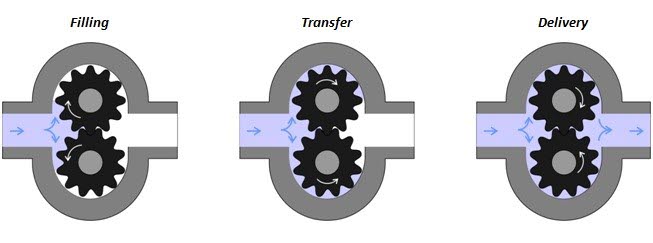

Their simple yet durable engineering enables them to be highly reliable. Their smooth flow allows for consistent fluid handling, thus rendering external gear pumps useful for processes which require metering and controlled flow rates. As well as this an external gear pump is also highly effective at handling a variety of different fluid viscosities allowing them to be utilised in a range of different processes and industries such as the oil and gas sector, chemical processing and many more.

External gear pumps also have a self-priming capability as a result of their rotating gears removing any air in the suction line, allowing them to run dry and also contributing towards low noise levels. As well as this, Internal gear pumps have spur gears, which allow the ability to flow in any direction. Thus making them great for filling and emptying containers or in processes where excess fluid needs to be returned to prevent it from sitting in pipework. External gear pumps are typically available with either spur gears, meaning that they are also bi-directional, or herringbone gears, which are for particularly viscous fluids but do not allow reversible flow.

When to use External Gear pumps

External gear pumps have various applications across a range of industries as a result of their efficiency, reliability, and general ability to handle a variety of fluids:

-

Lubrication Systems: External gear pumps are widely used in machinery and equipment for lubrication purposes. They efficiently transfer lubricating oils and fluids to different components, ensuring smooth operation and reducing friction, wear, and tear.

-

Fuel Transfer: External gear pumps are widely utilised in fuel transfer applications, such as in automotive fuel systems, fuel dispensing stations, and fuel supply to engines and generators. Their ability to handle various fuels renders them suitable for a range of fuel transfer needs.

-

Chemical Transfer and Processing: An exeternal gear pump is brilliant at transferring a range of chemicals in industries such as pharmaceuticals, petrochemicals, and chemical processing. Their precise flow control and compatibility with a wide range of fluids make them valuable assets for chemical transfer and processing applications.

| Application | Internal | External |

| Chemical additives,mixing and Blending |

|

|

| Soaps and surfactants |

|

|

| Alcohols and solvents |

|

|

| Acids and caustic (stainless steel or composite construction) |

|

|

| Glycol |

|

|

| Food Production |

|

|

| Asphalt, Bitumen, and Tar |

|

|

| Paint, inks, and pigments |

|

|

| Various fuel oils and lube oils |

|

|

| Industrial and mobile hydraulic applications (log splitters, lifts, etc.) |

|

|

| Low volume transfer or application |

|

|

| Resins and Polymers |

|

|

| Polyurethane foam (Isocyanate and polyol) |

|

How to Maintain external gear pumps

It is crucial to undergo routine maintenance and inspection of gear pumps to ensure that your pump runs smoothly, and decrease the likelihood of unforseen expenses on repair costs.

It is recommended to check the bearings regularly. Bearings are essentially the most important maintenance area for gear pumps, this is because in the event that they are misaligned or defective, this may lead to imbalance. Check bearings regularly and get rid of defective bearings with a puller when necessary. Excessive noise is typically a large indicator of wear on the pumps bearing.

Check gear pump clearance. The new gear pump has a clearance of 0.009 to 0.007 inches with the teeth and cavity of the gear. Attempt to pass a piece of paper inbetween the gaps and frequently check the wear of the teeth. If it is easy to pass through the gap, it indicates that the bearing has been worn and need replacing.

By following a routine maintenance schedule and following the correct operating procedures, gear pumps tend to be an effective solution for high viscosity pumping requirements.

How to select external gear pumps

- Fluid Viscosity: External gear pumps are capable of handling various fluid viscosities. However, it's essential to know the viscosity of the fluid being pumped, as this can have an affect on the efficiency of the pump. Select an external gear pump that is appropriate for the viscosity of the fluid in your application.

-

Flow rate: Gear pumps have a flow rate which dictates the capacity or volume of fluid that they can handle passing through the system over a given time. When it comes to pump selection, the flow rate of both the system and the pump should be matched.

-

Materials of Construction: External gear pumps are available in a range of materials, including cast iron, stainless steel, and various alloys. Consider the chemical compatibility of these materials with the fluid being pumped. For corrosive or abrasive fluids, select a pump with materials that provide adequate resistance.

-

NPSH (Net Positive Suction Head) Requirements: Pay close attention to the NPSH requirements of the pump. NPSH is critical for preventing cavitation, and ensuring that the pump's NPSH requirements match the available NPSH in the system is essential for reliable and efficient operation.