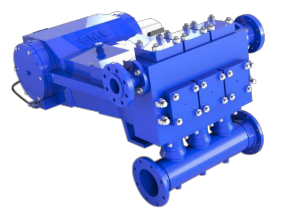

High Pressure Piston & Plunger pumps from AxFlow UK

Piston and Plunger Pumps

1 series from 1 manufacturers

All components are constructed from robust materials in order to accommodate high pressures, high piston speeds, high temperatures and potentially corrosive or aggressive fluids. Compact designs make them ideal for restricted spaces and suitable for skid-mounting and integration with existing plant.

Because of the reciprocating action of the plungers and pistons, energy is transferred directly to the fluid resulting in high levels of efficiency. Both pump types provide efficiency ratings between 85 and 90 percent making them an attractive proposition where energy savings have a significant impact on pump selection. Depending on the types of fluid pumped and number of cylinders, both pump types can achieve pressures up 1500bar and flow rates up to 1000mӠ/hr.

How Piston and Plunger pumps work

Piston and plunger pumps are high efficiency pumps which operate on the principle of a rotating crankshaft driving one or more reciprocating rods to draw fluid into the pump chamber and discharge it at a pressure dictated by the application. Both pumps are very similar in that they employ reciprocating connecting rods driven by a crankshaft which activates the plunger or piston in the pump chamber (cylinder). Where they differ is in the sealing mechanism and it this which influences the performance in discharge pressures.

The difference between the two designs lies in the sealing mechanism separating the crankshaft mechanism from the pump chamber. The plunger pump uses a static high pressure seal fixed to the chamber wall so the plunger moves back and forth through the fixed seal with a smooth action. The piston pump uses high pressure seals attached to the piston rod and move with the reciprocating action of the rod. However, this results in increasing on the wear on the seals. Because there is less friction on the seal in the plunger pump, it is able to achieve higher discharge pressures than the piston pump.

Plunger Pumps

Plunger pumps operate across a wide range of pressures and flow rates and any changes to the flow rate or pressure have only a minimal impact on pump performance. On start-up, the plunger shuts moves back closing the outlet valve and opening the inlet valve, thereby pulling fluid into the pump chamber. Once the chamber is full the continuing forward action of the plunger puts pressure on the inlet valve and opens the outlet valve for the fluid to be discharged at a predetermined pressure.

Any concerns in respect to uneven or pulsing flow can be addressed by using either pulsation dampening elements in the pressure and suction line or by using multiple-cylinder pumps. Where pulsation could be detrimental to the application, the recommended solution is to use a triplex (three cylinders) pump as this delivers a smooth fluid flow. Compared to the Piston pump, the Plunger has relatively few components, the main ones being the crankshaft, piston rod, seal, inlet and outlet valves, cylinder head and drive mechanism.

Piston Pumps

Piston pumps fall into two categories, namely axial flow and radial flow.

Axial piston pumps use a number of pistons inside a rotating cylinder block and a stationary eccentrically positioned swashplate. As the drive shaft rotates the angle of the swashplate changes, driving the spring-loaded pistons in and out of the individual cylinders. This action pulls fluid into the cylinder block and expels it through the discharge port.

Radial piston pumps contain an eccentric shaft that pushes radially positioned cylinders containing pistons, which are mounted on a rotor hub. As the rotor turns, the pistons move sequentially in and out of their cylinders causing the fluid to be sucked into the cylinder cavity and then discharged at a higher pressure. Simultaneously a valve inside the piston opens to allow new fluid into the piston. The valve prevents the pressurized fluid at the discharge port from returning into the piston cavity. This design delivers high efficiency and very high-pressures at low speeds, even at very high loads.

Features and Benefits of piston and plunger pumps

- Wide pressure range with certain types delivering top pressures in excess of 1000bar.

- High levels of efficiency.

- Pump low flows at high pressures.

- Ability to pump viscous and non-lubricating fluids.

- Wide range of material options for plungers, pistons and cylinders.

- Self-priming.

- Drive options include electric motor, diesel engine and belt drive.

- Wide range of pump sizes and options.

- Simple flow control without affecting performance.

- Intermittent and continuous flow capabilities.

Applications

Plunger and piston pumps are immediately associated with water jetting and pressure washing systems, where they have a significant presence due to their high pressure, low flow capabilities and high efficiency. Where cleanliness and hygiene are a priority, such as in food and drinks processing, these pumps can be easily integrated into the existing water circulation infrastructure and programmed into daily operating regimes. Other cleaning applications can be found in waste water treatment, ceramics, paper and pulp and metal recycling sectors where filter presses are employed. They equally as effective for cleaning ships’ hulls, offshore platforms and agricultural premises and equipment.

In the food production chain they are employed for humidity misting, a capability now recognised in the construction and premises management where they are employed for fire suppression. In heavy industry the high pressure flows provide a resource for metal cutting, in low flow oil lubrication hydraulics systems and handling high viscosity fluids. In gas and oil recovery there are many applications where high pressure water is used for drilling and there is a requirement for used water to be re-injected. A piston or plunger type pump is effective in oilfield drilling delivering mud for drill bit cooling and returning drilling cuttings and waste to the surface.

More niche applications include hydrostatic pressure testing in laboratory environments, on board ship and vessel reverse osmosis, de-icing equipment in commercial transport, CO2 pumping for plant cooling and paint spraying booths.

Talk to AxFlow about piston and plunger pumps

Plunger and Piston pumps are exceptionally versatile pumps that can contribute to a great many processes where there is a demand for high pressure and a pulsation-free liquid flow. There are several design variations within these two pump technologies and AxFlow have made it their business to stablish a product portfolio that brings together the world’s leading manufacturers.

Piston and Plunger Pump Maintenance Best Practices

Effective piston and plunger pump maintenance is critical to ensure reliable high-pressure operation, accurate flow delivery, and long service life. As positive displacement reciprocating pumps, piston and plunger pumps are highly sensitive to wear, alignment, lubrication, and fluid cleanliness. A structured maintenance programme reduces downtime, leakage, and costly component failure.

Routine Inspection and Condition Monitoring

- Inspect for leakage at packings, seals, valve covers, and pump head joints

- Monitor discharge pressure, flow stability, and power consumption

- Listen for abnormal noise or knocking, which may indicate valve wear or cavitation

- Check bearing and crankcase temperatures for signs of lubrication failure

Valves, Packings, and Pump Head

- Inspect suction and discharge valves for wear, pitting, fouling, or spring fatigue

- Clean or replace valve seats, discs, and springs to maintain sealing efficiency

- Inspect packings and plungers/pistons for scoring, wear, or chemical attack

- Maintain controlled packing leakage for cooling and lubrication where specified

Lubrication and Drive Components

- Maintain correct crankcase oil level and oil quality

- Replace lubricating oil at manufacturer-recommended intervals

- Lubricate crossheads, bearings, and sliding components as required

- Inspect couplings, belts, or gear drives for alignment and wear

Alignment, Cooling, and Suction Conditions

- Verify pump-to-motor alignment after installation and maintenance

- Ensure cooling systems for packings or plungers are operating correctly

- Maintain adequate NPSH available (NPSHa) to prevent cavitation

- Keep suction strainers clean and free from restrictions

Planned Maintenance and Overhaul

- Schedule overhauls based on operating hours, pressure, and fluid severity

- Measure plunger straightness, surface finish, and dimensional wear

- Replace worn packings, valves, seals, and bearings before performance degrades

- Inspect pump frames and heads for fatigue, corrosion, or cracking