Hygienic screw pumps are positive displacement pumps that use one or several screws to move fluids or solids along the screw(s) axis.

Screw Pumps

1 series from 1 manufacturers

How Screw Pumps Work

Screw pumps are positive displacement rotary pumps that move fluid axially along rotating screw elements, delivering continuous, low-pulsation flow. They are widely used for viscous, shear-sensitive, multiphase, and high-pressure fluids in industrial, chemical, oil & gas, and hygienic process applications.

Operating Principle

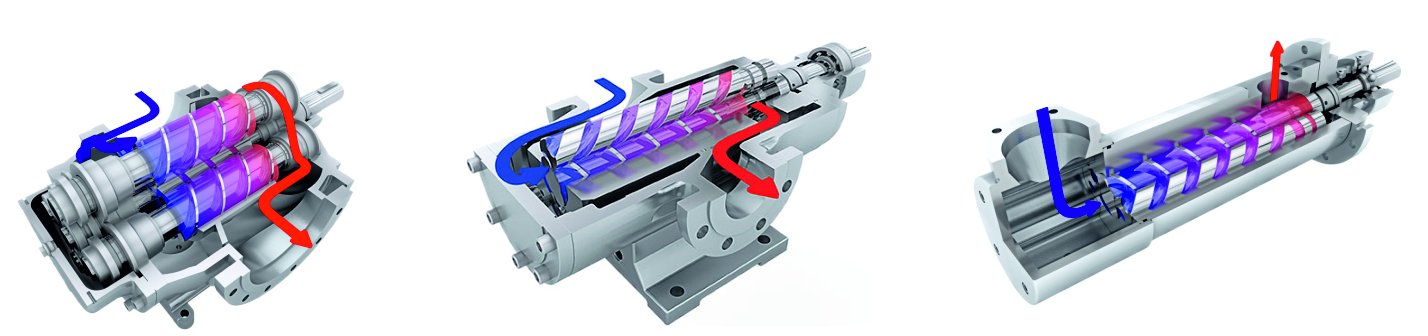

A screw pump uses one or more intermeshing helical screws rotating within a close-fitting casing.

- As the screws rotate, sealed cavities are formed between the screw flights and the pump casing.

- Fluid enters at the suction end and is trapped within these cavities.

- The rotation of the screws transports the fluid axially toward the discharge without compression.

- At the discharge end, decreasing cavity volume forces fluid out at a controlled, uniform rate.

Because flow is continuous and axial, screw pumps produce minimal pulsation, low shear, and stable pressure.

Key Technical Characteristics

- Positive displacement operation: Flow is proportional to rotational speed

- High volumetric efficiency across a wide viscosity range

- Excellent suction performance with low NPSH requirement

- Low internal turbulence, ideal for shear-sensitive fluids

- Pressure capability independent of flow rate

Types of Screw Pumps

- Single-screw (progressive cavity): High suction lift and solids handling

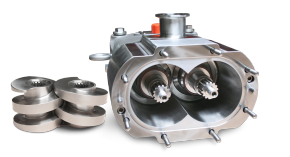

- Twin-screw: Bi-directional flow, CIP/SIP capable, hygienic designs

- Triple-screw: High-pressure, clean fluid transfer (fuels, lubricants)

Why Screw Pumps Are Efficient:

Unlike centrifugal pumps, screw pumps displace a fixed volume per revolution, maintaining stable flow even with pressure or viscosity changes. This makes them ideal for precision transfer, metering, and continuous process duties.

Advantages of screw pumps

- A simple design makes it heavy duty with minimal wear.

- Twin screw pumps can run in either direction allowing them to deliver a bi-directional flow.

- Smooth handling, operating a range of flows and pressures.

- Versatility with ability to pump at a range of flow rates, pressures, liquid types and viscosities

- Self-priming characteristics

- High tolerance for entrained gases or air.

- Eliminate slip pulsations in low viscous, high pressure applications

- Low NPSH requirement when emptying tanksWide range of flow capabilities (run speeds up to 3500 RPM)

Typical applications for screw pumps

Twin screw pumps are most suitable for hyienic aplications that would benefit from a pump that can handle fluids with different viscosities. The most common of such appliactions is where the pump is required to pump the product and also CIP fluids. This application is very common in confectionary production settings.

Most multiple-screw pump designs are self-priming and are able to effectively work with low suction pressure. They also tend to be gas tolerant and are able to handle free and entrained gases without vapor locking. Low internal fluid velocity and the gentle meshing of the rotors also contribute to low shear rates, which is especially important for sheer-sensitive emulsions.

Twin screw pumps are also fantastic for Product & CIP pumping applications.

WHY BUY SCREW PUMPS FROM AXFLOW

The Waukesha Universal TS range is a new and innovative positive displacement twin screw pump for hygienic applications. This precision pump offers a gentle flow and the ability to pump both product and CIP therefore reducing overall process costs considerably.

The Waukesha Universal Twin Screw pump is designed to handle a vast range of liquids, ranging from very thin to highly viscous fluids making it suitable for applications across different industries, such as food and beverage, pharmaceuticals, chemicals, and petrochemicals. The twin screw pumps ability to handle a diverse range of fluids decreases the need for multiple types of pumps, thus simplifying your overall fluid handling process.

How to select a screw pump

Selecting the correct screw pump is essential for achieving smooth, low-pulsation flow, high efficiency, and long service life in demanding industrial and process applications. Screw pumps are positive displacement pumps ideal for handling viscous, shear-sensitive, and multiphase fluids with consistent flow and minimal pressure fluctuation.

- Define Flow and Pressure Requirements

- Flow rate: Screw pump flow is proportional to rotational speed; size the pump to meet required throughput with sufficient turndown.

- Differential pressure: Confirm the pump is rated for maximum operating pressure, including cold-start and high-viscosity conditions.

- Evaluate Fluid Properties

- Viscosity: Screw pumps perform efficiently across a wide viscosity range.

- Shear sensitivity: Continuous axial flow makes them suitable for shear-sensitive products.

- Solids and abrasives: Select hardened materials or coatings where solids are present.

- Temperature and chemistry: Ensure wetted materials and elastomers are chemically and thermally compatible.

- Pump Type and Configuration

- Single-screw (progressive cavity): Excellent suction capability and solids handling.

- Twin-screw: High efficiency, bi-directional flow, and excellent CIP performance.

- Triple-screw: High-pressure, clean fluid applications such as fuels and lubricants.

- Efficiency and Control

- Select a pump operating near its optimal speed range to minimise wear.

- Use VFDs for precise flow control and reduced energy consumption.

Consider maintenance access and lifecycle cost when finalising selection

If you pick out the incorrect screw pump, is likely to lead to unnecessary difficulties. The wide range of screw pumps all have their own advantages. It is key to understand their respective characteristics, in order to better achieve energy saving, material saving, increase efficiency or meet some special requirements.

We provide screw pump selection, performance evaluation, and refurbishment services across industrial, chemical, energy, and process applications.

Screw Pump Maintenance

Proper screw pump maintenance is essential to maintain volumetric efficiency, prevent rotor wear, and ensure reliable operation in positive displacement pumping systems.

- Monitor vibration, noise, and discharge pressure for early signs of wear or misalignment

- Maintain correct lubrication oil level and cleanliness in bearing and timing gear housings

- Inspect screws, liners, and clearances for wear, scoring, or erosion

- Check mechanical seals and shaft seals for leakage

- Ensure clean, unrestricted suction to maintain adequate NPSH and prevent cavitation

Scheduled inspection and timely replacement of wear components minimise downtime and extend screw pump service life.