what do apv manufacture

These industrial solutions combine the extensive array of heat exchangers, pumps, homogenizers and valves.

APV POSITIVE DISPLACEMENT PUMPS

The APV DW range of rotary positive displacement pumps is designed for a variety of hygienic and industrial applications. The pulse-free pumping action of the DW pump minimizes damage to particulates within the product.Thermal jackets can be fitted to facilitate the heating or cooling of the pump chamber before product entry. Rectangular inlets are available to improve inlet conditions for high viscosity fluidsand pressure relief valves can be provided to avoid over pressurization of th e pump.

The APV R Series pump line meets 3-A COP requirements and are known for easy disassembly and clean up equaling low maintenance costs. The R Series pumps are operating in thousands of applications in the food,beverage, brewing, meat, bakery, chemical and related industries and arealso known all over the world for their rugged, long-lasting design and efficient performance.

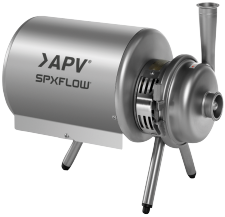

APV CENTRIFUGAL PUMPS

The PUMA+ Range comprises 3 basic pump configurations offering heads up to 78 m, flow rates up to 135 m3/h, and system pressures up to 16 bar. The Puma Range is widely used in the brewery, distillery, food and dairy industries.

APV W+ pumps ensure maximum efficiency and reduce noise and vibration levels to an absolute minimum. The W+ series consists of 17 standard models with pressure and flow capacities from 34 l/min to 1624 l/min and differential heads of up to 150 metres.The W+ pump and Ws+ are based on a unique hydraulic design that combines maximum efficiency with the highest sanitary standards. A critical design feature of the W+ is the APV brand patented spiral volute, which is positioned in the back plate of the pump. The volute increases efficiency and reduces turbulence,ensuring gentle product handling.

APV HOMOGENIZERS

With the APV product portfolio, SPX Flow offer a wide range of homogenisers covering laboratory applications, pilot plant machines through to large scale production homogenisers. Their Rannie and Gaulin brands have been synonymous with homogenisation for 100 years - are relied upon by the world's leading manufacturers across the Dairy, Food & Beverage, Pharmaceutical, Healthcare, chemical and the Biotech sectors. The Rannie and Gaulin technologies offer a large selection of features, build options, materials and multiple homogenising valve technologies. Combined this with extensive experience across all industries, and SPX Flow has the ability to deliver customised homogenisers specific to the customer's application. All APV homogenisers are 3A approved, comply with EN1935:2004 and are CE marked. If required, they can be supplied with FDA approved packing.

LABORATORY HOMOGENIZERS

APV’s laboratory homogenisers are ideal for researching new products and improving existing ones. The results of trials will give the required mean particle size and uniform distribution needed for product development. Trials conducted on APV’s laboratory homogenisers are fully reproducible for emulsions, dispersions and cell disruptions and can be applied to full-scale production.

pROCESS HOMOGENIZERS

Rannie homogenisers have an extensive range of build options available to them, ensuring a solution tailored for each specific application. Gaulin developed the first homogeniser in 1900 and introduced it at the World’s fair in Paris. Since then Gaulin machines have been market leaders for innovative homogenisation technologies. In 1972 APV, an SPX Flow brand, acquired Gaulin.

apv valves

With over 50 years' experience, AxFlow has a wealth of knowledge helping you choose the correct valve for your application. AxFlow GB is the exclusive distributor of APV valves in the UK. Its wide range of hygienic valves is suitable for industries such as pharmaceutical, food & beverage, and personal care. Their range of valves includes; Butterfly valves, Mix-proof valves, Shut-off valves, Safety valves.

Click here to check out more on the valves we provide.

APV HEAT EXCHANGERS

AxFlow UK specialise in the supply of high specification APV heat exchangers. We offer three very different types of heat exhangers giving us the ability to respond to nearly every application. Since APV invented the plate heat exchanger in 1923 they have been pioneering heat transfer technology around the world. APV heat transfer solutions provide cooling, heating, condensing and evaporation of process fluids - designed to solve heat transfer process challenges in a vast array of industries. Click on here to learn more about the heat exchangers we supply.

WHAT MAKES APV SPECIAL

APV, an established centennial engineering legacy, is an important part of the SPX FLOW brand, integrated over a decade ago. Addressing the food/beverage, dairy, pharmaceutical and healthcare markets, APV offers highly effective turnkey automation and process engineering solutions. These industrial solutions combine the extensive array of heat exchangers, pumps (rotary, centrifugal), valves, mixers, dissolvers and homogenizers that we manufacture with numerous services which will maximize the effectiveness of systems throughout the whole of their life-cycle. These services cover original system inception, equipment deployment, upgrades and eventual decommissioning, as well as plant optimization.

APV industrial process solutions are leaders in operational performance and consistency. Beyond performance, APV aftermarket services are integrated to establish safety and efficiency.

WHY BUY APV PRODUCTS FROM AXFLOW

AxFlow is APV's exclusive distributor for the UK

Engineering excellence, innovative design, and stringent quality control ensure that the APV range complies with the highest standards for hygiene and performance.

The necessity to deliver consistently safe, high-quality products requires manufacturers to make plant hygiene a top priority. APV's process products are designed for easy clean ability while minimizing the use of valuable resources such as energy. Many APV branded products have built-in intelligence for improved efficiency and total integration with modern control and automation systems.

All APV products are designed to meet international standards such as 3-A, USDA, ASME, EHEDG, FDA and the European CE Mark. APV is also helping its customers meet food safety legislation such as EC 178/2002 and the Bioterrorism Act of 2002.

APV's product range breaks down into 4 main areas: