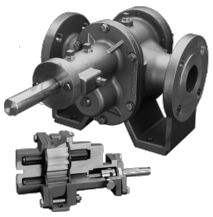

External gear pumps utilize two external gears rotating in the same direction within a close-fitting housing. As these gears rotate, fluid fills the spaces between the gear teeth and gets pushed out through the outlet.

External Gear Pumps

8 series from 3 manufacturers

-

- Adhesives

- Agriculture

- Aviation

- Beauty & Personal Care

- Building Services

- Ceramics

- Chemical

- Dairy

- Detergents

- Dye & Pigment

- Emulsions

- Fertilizers

- Fish Farming

- Heating, Water & Sanitation

- Nuclear Power Plants

- Offshore

- Oil & Gas

- Paint & Surface Coating

- Paints & Resins

- Paper Mills

- Petrochemical

- Pharmaceutical

- Plastic

- Power Generation

- Refineries

- Research & Development

- Surface Finishing

- Transportation

- Wastewater

- Water Treatment

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Ammonia

- Beer

- Bitumen

- Carbon Fibers

- Caustic Solutions

- Cereals

- China Clay Slurry

- Chocolate

- CIP Fluids

- Clay

- Coffee

- Concrete

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Cryogenic Liquids

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Temperature Oils

- High Viscosity Liquids

- HydrochloricAcid

- Hygienic Liquids

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Liquid CO2

- Low NPSH

- Low Viscosity Liquids

- LPG

- Meat

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toluene

- Toxic Liquids

- Ultra Pure Water

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

- Wine

- Wort

-

- Adjustable-Flow

- Canned

- Chemically Resistant

- Close-Coupled

- Compact

- Containment

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High Temperature

- High-Efficiency

- High-Performance

- Horizontal Mount

- Intrinsically Safe

- Low-Noise

- Magnetic Drive

- Mechanical

- Mechanical Seal

- Mobile

- Modular

- Non-Metal

- Oil-Free

- Pulse-less

- Rotary

- Sanitary

- Seal-less

- Self-priming

- Single-Stage

- Variable Speed

- Vertical

- Vertical-Mount

Do you need help finding the right pump that meets your needs?

We have experienced experts who are ready to help you!

Get in touch hereOperating Principle of External Gear Pumps

External gear pumps have two external gears that mesh and rotate in the same direction in a closely fitting housing. As these gears rotate, the space between the corresponding gear teeth fills with fluid which gets pushed out through the outlet as no fluid can pass between the teeth mesh.

Gear Interaction

Gear Interaction

External gear pumps comprise two gears with external teeth that mesh within a housing. Both gears rotate in the same direction, maintaining a close clearance with the pump housing. This rotation creates chambers between the gear teeth.

Fluid Movement

As the gears rotate, fluid is drawn into the pump casing as the teeth unmesh, creating an expanding volume. Fluid fills the spaces between the teeth as they rotate and then gets transported to the discharge side as the gear teeth mesh together, reducing the chamber volume and pushing the fluid out through the outlet.

Sealed Operation

The gears and pump housing maintain close tolerances, ensuring minimal leakage between the suction and discharge sides. This design enables efficient fluid transfer with relatively low internal leakage.

Flow Control

Like internal gear pumps, external gear pumps are positive displacement pumps, meaning they displace a consistent volume of fluid per revolution. This allows for precise control over the delivered flow rate based on the rotational speed of the gears.

Advantages of External Gear Pumps

- High-Pressure Capability: Ideal for applications requiring high-pressure, low-flow fluids.

- Precision Flow: Accurate for dosing chemicals, oils, and fuels in OEM components.

- Versatility: Suited for low to medium viscosity fluids.

- Applications: Hydraulic systems, power steering systems, fuel injection systems, and continuous dosing of chemicals, oils, and fuels.

Applications of External Gear Pumps:

- High-Pressure Low-Flow Fluids: Delivering fluids under high pressure.

- Precision Dosing: Used in OEM components and machinery for precise chemical, oil, and fuel dosing.

- Hydraulic Systems: Essential in hydraulic setups.

- Power Steering & Fuel Injection: Ensures efficient operation in these systems.

Important considerations when selecting External Gear Pumps

- Flow Rate: Choosing the correct external gear pump involves assessing the required flow rate. Inadequate rates might affect performance, while excessive rates could result in pressure irregularities and wear.

- Viscosity: External gear pumps are proficient with low to medium viscosity fluids. Higher viscosity liquids might necessitate adjustments in gear speed for efficient handling.

Why buy External gear pumps from AxFlow?

AxFlow provides a diverse range of External gear pumps tailored to various industries. Our experts offer comprehensive support, aiding in pump selection, specification, installation, and maintenance. Reach out to AxFlow for personalized guidance in choosing the ideal external gear pump for your specific requirements.