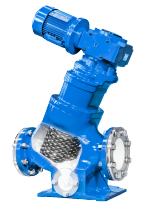

Industrial munchers are powerful and versatile machines that efficiently shred solid materials into smaller, manageable pieces. Designed for use across various industries, including wastewater treatment, biogas production, and industrial waste management, munchers ensure optimal performance with low energy consumption. With robust design, a long lifespan, and advanced control systems, munchers help minimise downtime and reduce operational costs.

Munchers and Grinders

3 series from 1 manufacturers

What is the Operating Principle of a Muncher?

An industrial muncher, also referred to as a grinder, operates by shredding solid materials into smaller, manageable pieces. The core mechanism consists of two counter-rotating shafts with hardened molybdenum steel blades. These shafts can be set to rotate at different speeds, generating optimal cutting force. The blades and spacers on the shafts vary in thickness, contributing to the effective reduction of material size. This design allows munchers to break down solid waste efficiently into smaller particles, suitable for further processing or disposal.

Advantages of Munchers

Munchers offer several key advantages for industrial operations. One of their main strengths is their ability to break down a wide range of materials effectively, such as textiles, branches, and fibrous waste like wipes and condoms. This versatility makes them highly valuable across sectors, from wastewater treatment to biogas production. Additionally, munchers are renowned for their energy efficiency, consuming less power compared to other shredding solutions, which helps reduce operational costs over time.

Another significant advantage of munchers is their durability and long lifespan. Thanks to their robust design and high operational efficiency, they typically require minimal maintenance. In fact, many munchers can run for up to two years without needing servicing, although annual inspections are recommended to ensure optimal performance. Moreover, these machines are equipped with advanced control systems, such as built-in PLCs, which provide overload protection. If a blockage occurs, the muncher can automatically reverse operation up to three times to clear the obstruction. Should the blockage persist, the system will shut down, protecting the motor and minimising downtime.

However, there are some risks associated with munchers. Despite being designed to handle various materials, they can still encounter blockages, especially if non-processable items enter the system. While the built-in protection mechanisms reduce the likelihood of serious damage, persistent jamming may still require manual intervention.

In What Applications Are Munchers Used?

Munchers are highly adaptable machines used across a wide range of industrial and waste management sectors. Their ability to break down solid materials efficiently makes them a valuable asset in many specific applications:

- Wastewater Treatment Facilities: One of the most common uses for munchers is in wastewater treatment plants, where they are installed in both vertical and horizontal pipelines. In this context, munchers play a critical role by shredding solid waste such as textiles and fibrous materials before it enters treatment tanks or centrifuges. This process helps prevent blockages and ensures smoother, more efficient operation of the treatment systems.

-

Biogas Production: In biogas facilities, munchers are essential for the efficient breakdown of organic materials. They shred food waste, plant matter, and other biodegradable materials into smaller pieces, accelerating the decomposition process. This facilitates easier conversion of these materials into biogas, improving overall energy production. Their efficiency in handling high volumes of organic matter is especially beneficial in large-scale biogas plants.

Industrial Waste Handling: Munchers are commonly used in heavy industries such as slaughterhouses, fish processing plants, and airports, where waste management is a major concern. In these environments, munchers help reduce the size of industrial waste, including bones, animal remains, and fibrous materials, to prevent blockages in pumps and pipelines. By ensuring the waste is properly macerated, they help maintain the smooth operation of processing and transport systems.

- Municipal Waste Processing: Municipalities also rely on munchers to manage solid waste in sewage systems. Solid materials like wipes, textiles, and other fibrous debris can cause serious problems if they enter sewage treatment plants. Munchers help mitigate this risk by breaking down these materials before they reach pumps, preventing blockages and ensuring uninterrupted wastewater processing.

Why Buy Munchers from AxFlow?

We offer a comprehensive range of industrial munchers tailored to the needs of various industries and applications. By choosing AxFlow, you benefit from expert guidance provided by our highly experienced process engineers, ensuring you receive the ideal muncher for your specific requirements. Our team has access to leading manufacturers and cutting-edge technology, guaranteeing that you get the best equipment available on the market.

If you're unsure which muncher best suits your needs, don't hesitate to get in touch with us. We provide expert advice and personalized recommendations to ensure your operations run smoothly, with reduced downtime and increased productivity.