The circumferential piston pump is a compact unit that uses the same operating principle as the rotary lobe pump, whereby interlocking rotors move a fixed volume around the pump chamber. Where they differ is in the shape of the rotors, which in the case of the circumferential piston pump are arc shaped. The arc-shaped rotary pistons, or “wings”, have large heads which follow the profile of the pump body and travel in annular-shaped cylinders machined in the pump body. They also utilise a ‘rotor hub’ on the pump body which drives the rotary pistons on independently rotating shafts. Timing gears create a low-pressure cavity at the inlet side that helps introduce fluid into the pump.

Circumferential Piston Pumps

4 series from 1 manufacturers

-

- Acetate

- Adhesives

- Agriculture

- Bakery and confectionery

- Beauty & Personal Care

- Brewing and beverages

- Building Services

- Ceramics

- Chemical

- Clay

- Convenience food

- Dairy

- Detergents

- Dye & Pigment

- Emulsions

- Fish Farming

- Food & Beverage

- Fruit Concentrates

- Meat Processing

- Mechanical Engineering

- Oil & Gas

- Oil Fats & Mayonnaise

- Paint & Surface Coating

- Paints & Resins

- Paper Mills

- Pet Food

- Pharmaceutical

- Plastic

- Refineries

- Research & Development

- Rubber

-

- Abrasive Liquids

- Beer

- Biological Broths and Slurries

- Chocolate

- CIP Fluids

- Clay

- Coffee

- Dairy Products

- Detergents

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Temperature Oils

- High Viscosity Liquids

- Low Viscosity Liquids

- Meat

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Personal Care Products

- Pet Food

- Sauces

- Sensitive and Viscous Fluids

- Sewage

- Soaps and Detergents

- Synthetic Fibers

- Thixotropic Fluids

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wine

- Wort

-

- Abrasion Resistant

- Adjustable-Flow

- Aseptic

- Automatic

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Mechanical

- Mechanical Seal

- Mobile

- Modular

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Self-priming

- SIP

- Solids Handling

- Variable Speed

- Vertical

- Vertical-Mount

External Circumferential Piston (ECP) pumps are the next evolutionary step from rotary lobe pumps and offer a more precise, dependable and gentler pumping action along with higher performance capabilities.

How ECP Pumps Work

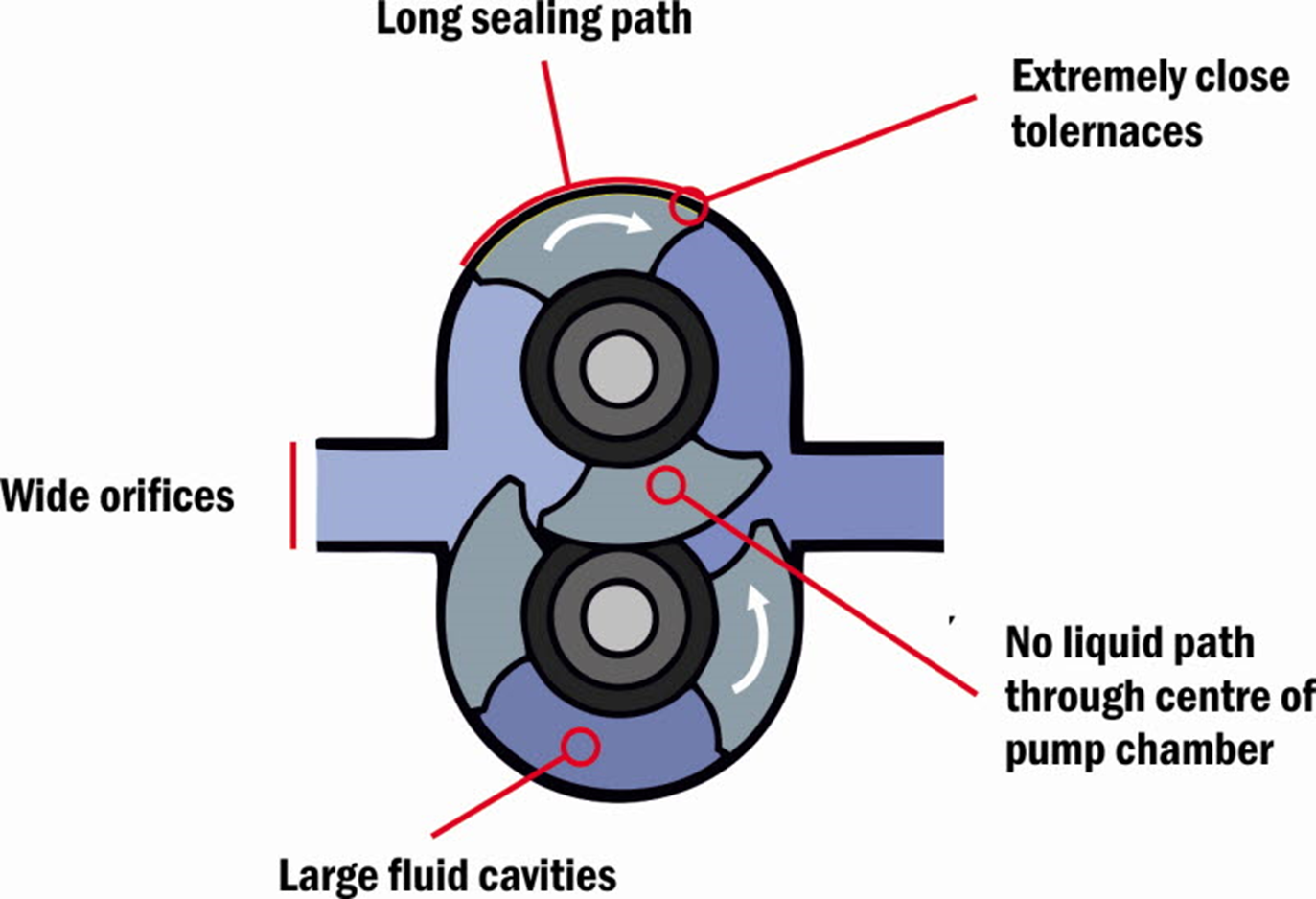

They operate on the circumferential piston principle whereby arc shaped rotor wings (pistons) arc, travel in annular shaped cylinders machined in the pump body. This results in a long sealing path, wide inlet/outlet orifices and large fluid cavities.

Advantages of External Circumferential Piston Pumps

The long sealing path reduces slippage and produces a smooth flow of product without destructive pulses or pressure peaks, and without valves or complex parts.

The wide orifices and large fluid cavity allow ECP pumps to handle large solids and abrasive liquids. The combination of these features means that ECP pumps offer a gentle pumping action with reduced risks of burning sensitive liquids.

ECP pumps have timing gears that are locked with key & keyways as are the rotors which eliminates the risk of timing gears slipping. The added advantage being no requirement for tricky re-timing the rotors following maintenance procedure.

- no slippage on product over 200 cP.

- an extremely gentle and smooth pumping action,

- the ability to handle viscous fluids of up to 200,000 cP,

- no galling or seizing.

- an increased priming capability.

- Higher pressure capabilities.

- No product ingress between rotor face and rotor case.

How to maintain ECP pumps?

There are four main areas that need consideration when it comes to maintaining the performance of an external circumferential piston pump.

- The tolerances in the pump chamber are critical as the pump’s ability to eliminate slippage and maintain a precise performance are extremely reliant on the close fit between the pistons and the chamber’s internal surfaces.

- The running speed and rotational consistency can be effected by damped or worn gears.

- The condition of the bearing should always be monitored as any defect in the bearings can result in a sudden and catastrophic pump failure due to the forces involved with many ECP applications.

- Perhaps more than most pumps, the mechanical seal should be regularly inspected in an ECP pump due to the nature of most ECP applications and the implications if there is any ingress of external contamination into the pumped product

How to select ECP pumps?

There are several areas of consideration when it comes to selecting the correct ECP pump.

Under sizing a pump and using a faster running speed will often lead to the generation of heat in the pump chamber that subsequently damages the pumped fluid,

The fluid characteristics that need to be considered for many ECP applications are greater than many pump duties and not only cover the normal parameters such as viscosity and temperature, but also the nature of any solids, it’s susceptibility to heat damage and it’s abrasiveness.

When it comes to the wider process the accuracy of the flow rate can be more critical than normal and the details of the suction conditions more important if the duty involves a viscous fluid.

Why buy ECP pumps from AxFlow?

AxFlow have over 40 years’ experience with ECP pumps and throughout this time have been associated with the technology leading Waukesha Universal range of products. The Universal suite of ECP pumps is comprised of 5 separate ranges covering a wide performance range, seal types and constructions; this allows Axflow to offer the best technical and cost effective solution.

In addition to this Waukesha Universal ECP pumps have rotor wings manufactured to extremely close tolerances from non-galling Alloy W88 and are designed with no cavity between the rotors, as is the case with rotary lobe pumps, to allow the passage of fluid.

The way Waukesha ECP pumps are manufactured allows them to be refurbished using oversized rotors and slightly enlarged chambers to prolong their service life and do not suffer from the problem of timing slip as can often be experienced with rotary lobe pumps