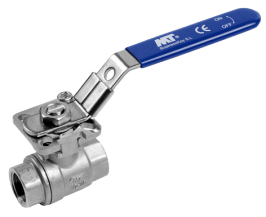

Ball valves are mechanical devices used to control the flow of fluids in pipelines. They consist of a spherical disc (the ball) with a hole through it that can be rotated to either allow or block the flow of fluid.

Ball Valves

2 series from 1 manufacturers

The Operating Principles of a Ball Valve

Ball valves operate on a simple yet effective principle to control the flow of fluids within pipelines. When the valve is in the open position, the spherical disc, known as the ball, is rotated so that the hole or bore running through it aligns with the direction of the pipeline. This alignment creates an unobstructed pathway for the fluid to flow through the valve, allowing it to move freely along the pipeline.

Conversely, when the valve is closed, the ball is turned perpendicular to the pipeline, effectively blocking the flow of fluid entirely. In this closed position, the bore of the ball is no longer aligned with the pipeline, creating a barrier that prevents any further movement of the fluid through the valve. This ability to completely shut off the flow makes ball valves highly effective for applications where precise control is required.

The operation of ball valves is typically straightforward. They are often equipped with a handle, lever or actuator attached to the valve stem. By turning this handle, lever or actuator, the valve operator can rotate the ball inside the valve body, thereby adjusting the position of the bore and controlling the flow of fluid through the pipeline. This operation provides users with a convenient and reliable means of on/off regulation of the flow of fluids in a wide range of industrial applications. Additionally, it's worth noting that ball valves can also be configured to regulate the flow by incorporating a V-port design. This modification allows for more precise control of flow rates, making them suitable for applications requiring enhanced control capabilities.

Advantages & Disadvantages of Ball Valves

Ball valves are everywhere in industries because they're known for being dependable and easy to use. But to pick the right valve for a job, it's important to know what they're good at and where they might fall short. So, let's take a closer look at what makes ball valves great, as well as where they might have some limitations. This way, we can better understand when and where they shine brightest in different situations.

Advantages of Ball Valves

Ball valves offer several advantages that make them suitable for various industrial applications:

- Quick Operation: With their simple design and manual operation, ball valves can be opened and closed rapidly, allowing for efficient flow control.

- Minimal Pressure Drop: When fully open, ball valves provide a straight-through flow path, resulting in minimal obstruction and low pressure drop across the valve.

- Reliability: Ball valves are known for their robust construction and reliable performance, making them suitable for high-pressure and high-temperature applications.

- Versatility: Ball valves can handle a wide range of fluids, including corrosive and abrasive substances, making them versatile for use in different industries.

- Ease of Maintenance: Their straightforward design and fewer moving parts simplify maintenance tasks, reducing downtime and operational costs.

Disadvantages of Ball Valves

Despite their advantages, ball valves also have some limitations:

- Throttling Limitations: Excessive throttling of ball valves can lead to premature wear and reduced service life, limiting their effectiveness in applications requiring frequent adjustments to flow rates.

- Potential Leakage: Depending on the seal design and quality, ball valves may experience some leakage, especially in high-pressure or high-temperature environments, which can affect system performance and efficiency.

- Size and Weight: Ball valves can be bulky and heavy, particularly in larger sizes, which may require additional support and space in the piping system.

Considerations when selecting Ball Valves

When selecting ball valves, consider factors like fluid type, pressure, and temperature requirements, as well as desired flow rate and control features. Ensure the valve's size and pressure rating match your system specifications for optimal performance and safety. Evaluate material compatibility for corrosion resistance and longevity. Check the seal mechanism to prevent leakage and maintain system integrity. Decide on manual or automated actuation based on control needs and preferences. Whether it's threaded, flanged, or welded connections, choose appropriate end connections for seamless integration into your piping system.

Considerations for selecting ball valves include various factors such as fluid type, pressure, and temperature requirements, as well as desired flow rate and control features. Here are some key points to keep in mind:

- Application

- Size and Pressure Rating

- Material Compatibility

- Sealing Mechanism

- Actuation

- End Connections

Why buy Ball Valves from AxFlow

AxFlow provides ball valves crafted to meet the unique needs of various industries and applications. At AxFlow, we pride ourselves on providing personalized advice from experienced process engineers and offering a diverse selection of top-quality process technology from leading global manufacturers. Need assistance in choosing the ideal valve for your specific requirements? Don't hesitate to reach out. Our team of experts and engineers is here to support you every step of the way, from selection and specification to installation and maintenance of your fluid handling equipment.