You need to look for savings where you can make them, for improvements where you can find them.

Our role within the food industry is vital. Bringing together our knowledge of pumps and fluid handling systems with your expertise in food production can result in winning solutions that save you money and bring competitive advantage.

Have a look at our Food & Beverage catalogue

Certifications for Hygienic Excellence

All our hygiene-focused products adhere to the strictest standards and certifications such as 3-A, EHEDG, EU 1935/2004, FDA, and more, ensuring compliance with food safety regulations and guaranteeing product integrity.

Complete Solutions for Food Processes

Understanding the complexity of food production, we design and install complete systems that cater to various needs within the food and beverage industry. From dosing and cleaning to cooling, our AxFlow Systems offer comprehensive solutions, optimizing efficiency and reliability throughout the food processing stages.

Challenges in the Food and Beverage Industry

In an industry facing increasing challenges—such as manufacturing high-quality products with tighter margins, adhering to stricter regulations, and innovating to meet the demands of a growing and more discerning customer base—our role is crucial.

By combining our expertise in fluid management systems with your food production knowledge, we can create advantageous solutions that save costs and provide a competitive edge.

Why choose AxFlow

At AxFlow, we cater specifically to the food and beverage industry, offering not just pumping and dosing equipment but also dispersing machinery, crushers, heat exchangers, analytical instruments, measurement, and control systems, mixing solutions, valves, top and side-entry agitators, and other accessories. Our engineers' expertise in fluid management processes in numerous applications makes a significant difference in these industries.

Our range includes

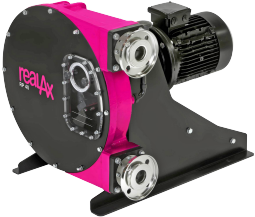

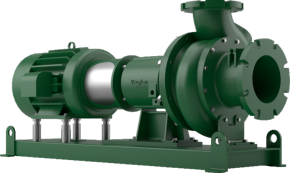

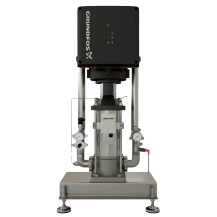

- Different Characteristic Pumps: Certified centrifugal and positive displacement pumps designed for various flow rates, offering reliable and robust operation with easy and cost-effective maintenance. Suitable for a wide variety of food, beverages, and pharmaceutical products.

- Reliable Valves for Various Processing Lines: Hygienically designed valves ideal for applications in dairy products, processed foods, beverages, breweries, as well as chemical and pharmaceutical industries. These valves are EHEDG tested and available in on/off and changeover versions.

- High-Efficiency Heat Exchangers: Meeting 3A and FDA standards, our heat exchangers offer efficient operation, compact size, durable construction, and flexible configurations with different frame materials, plates, and gaskets.

- High-Pressure Homogenizers for Uniform Products: Industrial-scale homogenizers designed for high flow rates and pressure ranges up to 1500 bar, ensuring stable and uniform products across industries like food, beverages, dairy, chemicals, cosmetics, and pharmaceuticals.

- Efficient Vacuum Solutions for Food and Beverage Processes: In the food and beverage industry, vacuum pumps play a pivotal role in various critical processes, ensuring product quality, shelf life, and maintaining a hygienic environment. These pumps are essential for applications like vacuum packaging, removing air from containers or packaging to extend product freshness, and creating controlled atmospheres to preserve food.