Optimize Your System Efficiency with NOV Mono Munchers

At AxFlow, we understand the challenges your systems face, from blockages to potential pump damage. That's why we offer tailored solutions featuring state-of-the-art NOV Mono Munchers. Our solid shredders are designed to protect your systems, ensuring uninterrupted operation even in the face of challenging materials.

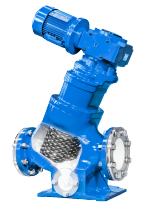

How NOV Mono Munchers Work

Our munchers employ slow-running double-shaft shredders equipped with intermeshing knives on each shaft. These knives rotate in opposite directions, providing "forced guidance" to solids within the system. Regardless of the material—be it fibers, plastics, textiles, wood pieces, rubber parts, disinfectant wipes, masks, beverage cans, or other foreign bodies—once within range of the slowly rotating knives, particles are effectively shredded.

Our Muncher Range

- Mono A Muncher

- Mono SB Muncher

- Mono EZstrip TR Muncher

Why Choose AxFlow's NOV Mono Munchers?

- Reliability: Our munchers guarantee uninterrupted system operation, minimizing downtime and ensuring consistent performance.

- Versatility: From fibers to plastics and everything in between, our munchers handle a wide range of materials, making them suitable for diverse industries.

- Innovation: With models like the EZstrip TR Muncher, we bring you cutting-edge technology for simplified maintenance, reducing service complexities.

- Tailored Solutions: AxFlow provides customized muncher solutions to meet your specific system requirements, ensuring seamless integration into your operations.

Trust AxFlow for superior muncher solutions that safeguard your systems, prevent blockages and optimize your processes. With our expertise and innovative products, you can achieve unparalleled efficiency and reliability in your operations. Contact us today for personalized consultations and discover how NOV Mono Munchers can revolutionize your system performance.