Thermal Service Fluids

Thermal service fluids are critical in systems where the transfer of heat is a primary function, such as in heating, cooling, or energy storage applications. These fluids must operate across a broad temperature spectrum, from cryogenic conditions for gases like liquid nitrogen, to high-temperature environments involving steam, oils, and molten substances. Industries such as power generation, chemical processing, and refrigeration rely on these fluids to maintain optimal thermal performance, ensure system efficiency, and manage energy transfer effectively.

- Pumping Cryogenic Liquids

- Pumping Process Condensate

- Pumping Refrigerants & Propellants

- Pumping Thermal Service Fluids

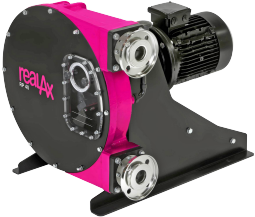

Sensitive and Viscous Fluids

Sensitive and viscous fluids are challenging to pump due to their high viscosity or sensitivity to shear forces. These fluids, such as adhesives, gels, creams, and food products, tend to resist flow and can be easily damaged or altered during transportation. For example, food products like chocolate and peanut butter, or industrial materials like epoxies and resins, need careful handling to preserve their quality. In industries like food processing, cosmetics, and manufacturing, specialized pumping systems are designed to manage these thick and sensitive substances without causing degradation or structural changes.

- Pumping Adhesive

- Pumping Biological Broths and Slurries

- Pumping Bitumen

- Pumping Chocolate

- Pumping Cosmetic Creams

- Pumping Gels

- Pumping Highly Viscous Fluids

- Pumping Molasses & Syrup

- Pumping Non-Newtonian Fluids

- Pumping Prepared Food

- Pumping Rheopectic Fluids

- Pumping Sensitive & Viscous Fluids

- Pumping Thixotropic Fluids

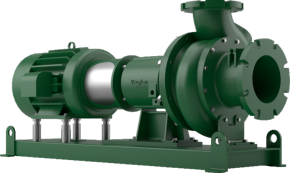

Solids Ladened Liquids

Solids-laden liquids are mixtures containing suspended solids, such as slurries, wastewater, or drilling fluids. These fluids are typically abrasive and may contain a variety of particles, including sand, gravel, paper pulp, or even waste materials. They require robust pumping systems capable of handling the increased wear and tear caused by solid content. Industries like mining, wastewater treatment, and agriculture frequently handle these mixtures, which can vary greatly in consistency and abrasiveness depending on the application.

- Pumping Aluminium Oxide Slurry

- Pumping Anaerobic Digestion

- Pumping Animal Waste

- Pumping Biological Broths and Slurries

- Pumping Calcium Oxide

- Pumping China Clay Slurry

- Pumping Liquids Containing Solids

- Pumping Produced Water

- Pumping Solids Ladened Liquids

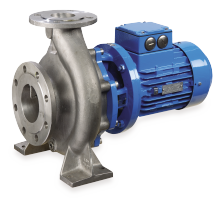

Corrosive and Toxic Liquids

Corrosive and toxic liquids are hazardous substances that can cause chemical reactions leading to the degradation of standard pump materials. These fluids, which include strong acids, alkalis, and toxic chemicals, are prevalent in industries like chemical manufacturing, pharmaceutical production, and waste treatment. Handling these liquids requires corrosion-resistant materials like stainless steel or specific alloys, as well as specialized containment to ensure safety and prevent environmental harm. Managing these substances properly is crucial to protecting workers and equipment while avoiding dangerous leaks or spills.

- Pumping Acids

- Pumping Ammonia

- Pumping Benzene

- Pumping Citric Acid

- Pumping Corrosive & Toxic Liquids

- Pumping Corrosive Dyes

- Pumping Ferric Chloride

- Pumping Hydrochloric Acid

- Pumping Hydrofluosilicic Acid

- Pumping Nitric Acid

- Pumping Phosphoric Acid

- Pumping Potassium Hydroxide

- Pumping Radioactive Fluids

- Pumping Silver Nitrate

- Pumping Sodium Hydroxide

- Pumping Sulphuric Acid

- Pumping Toxic Liquids

Thin Liquids

Thin liquids are low-viscosity fluids that flow easily, such as solvents, fuels, and light oils. These liquids are often found in industries like pharmaceuticals, petrochemicals, and food and beverage production. Despite their fluidity, they require precision in handling to prevent evaporation, contamination, or spillage. Pumps designed for thin liquids often need to ensure tight sealing and controlled flow rates, as many of these fluids are volatile, flammable, or reactive with air or other materials. Maintaining the purity and stability of thin liquids is critical in industries that require high levels of product integrity.

- Pumping Acetone

- Pumping Alcohol

- Pumping Ethanol

- Pumping Fuel

- Pumping Hexane

- Pumping LPG

- Pumping Low Viscosity Liquids

- Pumping Methanol

- Pumping Propanol

- Pumping Solvent

- Pumping Toluene

- Pumping Xylene

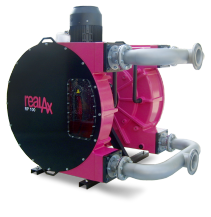

Abrasive Liquids

Abrasive liquids contain solid particles that can grind down equipment over time, such as slurries with sand, metal chips, or other hard materials. These liquids are frequently used in industries such as mining, construction, and metalworking, where the transportation of these mixtures is essential for production processes. Pumps designed for abrasive liquids must be built from materials that can withstand the erosive effects of the solid particles and provide reliable performance over extended periods of operation. Effective handling of abrasive liquids ensures the longevity of equipment and prevents costly downtime due to wear.

- Pumping Abrasive Liquid

- Pumping Aluminium Oxide Slurry

- Pumping Calcium Oxide

- Pumping China Clay Slurry