Heat exchangers play a vital role in liquid processing during production, whether you need to cool down, heat up or temper the processed liquid, you will need a high-quality heat exchanger

Heat Exchangers

HOW DO HEAT EXCHANGERS WORK?

Heat exchangers operate on the principle of indirect heat transfer. In this form of thermal convection, two media flow separately through the heat exchanger. Heat-conductive materials made of metal separate the two streams, allowing efficient temperature exchange between the two media.

ADVANTAGES OF HEAT EXCHANGERS

- Efficient thermal convection between two media

- Spatial separation of the two media by conductive materials

- Temperature control through cooling or heating

- Space-saving design with high efficiency

- Low maintenance requirements

TYPES OF HEAT EXCHANGERS

Indirect heat exchangers vary fundamentally depending on the industrial process and conveying medium. Common heat transfer systems include plate heat exchangers and scraped surface heat exchangers.

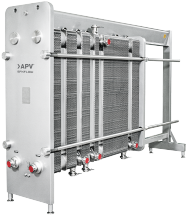

Plate Heat Exchangers

Plate heat exchangers consist of several specially shaped metal plates arranged sequentially. Sealed gaps between the plates are alternately traversed by the primary and secondary media, facilitating heat transfer. These heat exchangers, with features like electropolished surfaces, special seals, and components made of high-quality stainless steel, are suitable for processes with high hygienic requirements.

Scraped Surface Heat Exchangers

Scraped surface heat exchangers consist of a cylindrical housing whose outer walls can be heated or cooled by a secondary medium. When the product is heated or cooled, its viscosity can change significantly (e.g., thicker when colder). These heat exchangers are equipped with a rotating shaft with scrapers. During operation, the product is scraped off the heated or cooled walls by the scrapers, preventing product adherence to the walls. Simultaneously, the shaft creates turbulence in the product, ensuring uniform attainment of the desired temperature.

Tube Heat Exchangers

Tube heat exchangers are another widely used type of heat transfer system. In these exchangers, multiple tubes are arranged in a specific pattern within a shell. One fluid pass through the tubes, while the other flows around the outside of the tubes within the shell. This arrangement maximizes the surface area for heat exchange, allowing efficient transfer of thermal energy between the two fluids.

APPLICATIONS OF HEAT EXCHANGERS

In the food industry, heat exchangers are used to extend the shelf life of food products. Media such as juice and milk can be pasteurized through heat exchangers, reliably eliminating microorganisms and pathogens.

In processes of the chemical industry, heat exchangers are used for temperature control. Process technology enables the heating, cooling, condensation, as well as the evaporation and separation of aggressive media like sulfuric acid or ammonia.

In pharmaceutical applications, hygienic heat exchangers maintain a constant temperature level throughout the entire manufacturing process. Electropolished surfaces, stainless steel components, and the possibility of standardized cleaning procedures ensure the highest safety in hygienic industrial applications.

AXFLOW - YOUR CONTACT FOR HEAT EXCHANGERS

Are you looking for professional advice or do you have questions about heat exchangers? The dedicated team at AxFlow is here to assist you. Our specialists have extensive experience and knowledge in the field of heat exchangers. We are here for you, ensuring that you receive the best solution for your requirements. Feel free to get in touch with us.

7 series from 2 manufacturers

-

- Analysis

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Dual Dispensing

- Extraction

- Feed

- Filling

- Filtration

- Flow Control

- Greasing

- Grinding

- Handling

- Heating

- High-Pressure

- High-Temperature

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Metering

- Mixing

- Off-loading

- Powder Coating

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Rinsing

- Sampling

- Settling

- Spraying

- Tempering

- Transfer

- Treatment

- Unloading

- Volumetric Dispensing

- Washing

- Water-Jet Cleaning

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Aluminium Oxide Slurry

- Ammonia

- Beer

- Biological Broths and Slurries

- Bitumen

- Carbon Fibers

- Caustic Solutions

- Cereals

- China Clay Slurry

- Chocolate

- CIP Fluids

- Clay

- Coffee

- Concrete

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Cryogenic Liquids

- Crystalline Slurry

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Temperature Oils

- High Viscosity Liquids

- Hydrochloric Acid

- Hygienic Liquids

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Liquid CO2

- Low NPSH

- Low Viscosity Liquids

- LPG

- Meat

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toluene

- Toxic Liquids

- Ultra Pure Water

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

- Wine

- Wort

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Booster Sets

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Containment

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Mechanical

- Mechanical Seal

- Mixed Flow

- Mobile

- Modular

- Motorless

- Multi-Stage

- Non-Metal

- Oil-Free

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Seal-less

- Single-Stage

- SIP

- Solids Handling

- Variable Speed

- Vertical

- Vertical-Mount