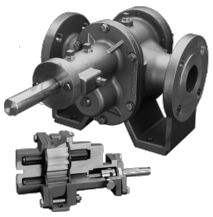

There are many thin liquids such as condensate, LPG, CO2 and most of these applications are typified by low NPSHa and liquids that provide poor lubrication for the pump. AxFlow have many pumps suitable for thin liquid duties available across the UK that can operate with low NPSHa and cope with poor liquid lubrication.

Here are some of the most common thin liquids that our products are designed to perform with:

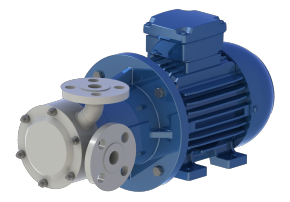

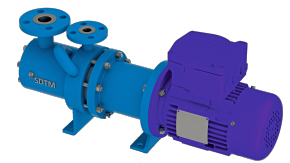

Pumping Thin Liquids? Maximise your process efficiency with our Mag Drive & Caanned Pumps!

When it comes to handling thin liquids like LPG, CO2, and methanol, you need pumps that can conquer low NPSHa challenges with ease. Our specialized Mag Drive & Canned pumps are engineered to excel in precisely these conditions, ensuring smooth, reliable, and safe fluid transfer. Say goodbye to cavitation and hello to optimum performance. Ready to supercharge your processes? Contact us today and discover how our low NPSHa pumps can elevate your efficiency and peace of mind in handling these critical fluids.

When it comes to handling thin liquids like LPG, CO2, and methanol, you need pumps that can conquer low NPSHa challenges with ease. Our specialized Mag Drive & Canned pumps are engineered to excel in precisely these conditions, ensuring smooth, reliable, and safe fluid transfer. Say goodbye to cavitation and hello to optimum performance. Ready to supercharge your processes? Contact us today and discover how our low NPSHa pumps can elevate your efficiency and peace of mind in handling these critical fluids.