Technical Support

AxFlow is built on specialist knowledge through our years of experience and talented collegues. Please contact our UK based team for specialist help and advice on your product selection and technical needs. Otherwise, please find a selection of help and data below on our product ranges, suppliers, case studies and helpful videos.

Datasheets & Manuals

Please click the link to go to the technical literature of the manufacturer you are interested in.

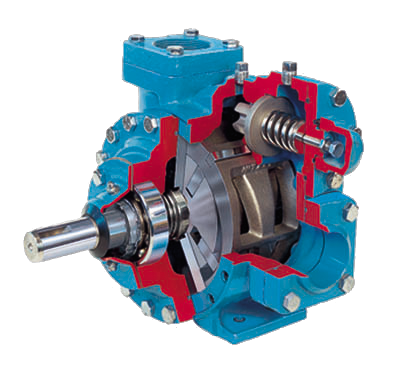

Read morePump Technologies

With such a wide product range, AxFlow offers numerous different pump technologies and designs to ensure we can offer the best solution for your application.

Read moreService Capabilities

AxFlow offers a comprehensive range of product services covering the installation, monitoring and maintenance of our products.

Read moreSystems

Our intimate knowledge of the key individual components such as pumps, heat exchangers and dispersion equipment that comprise food and beverage process equipment; makes us uniquely placed to...

Read moreTechnical Articles

A range of articles written by our technical experts covering the application of pump technologies to real life situations.

Read moreSubmersible pumping station & Smart technology

For the aviation industry to refurbish existing foul water drywell submersible pumping station incorporating new Flygt pumps and Smart technology

Read moreTechnical Library

AxFlow UK are creating a library of engineering data used in relation with pumps, valves and heat exchangers.

Read more