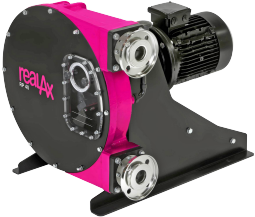

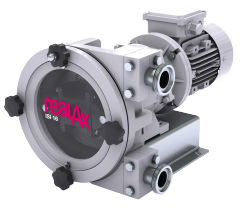

Hygienic Peristaltic Pumps

AxFlow UK's Realax range of tube pumps and hose pumps can be supplied with a range of different FDA compliant materials.

Hygienic peristaltic pumps are an ideal solution for the safe and contamination-free transfer of sensitive fluids in industries like food and beverage, pharmaceuticals, and cosmetics. These pumps work by compressing a flexible tube to move fluids, ensuring that the product only contacts the tubing, which makes them highly sanitary and easy to maintain.

AxFlow supply a range of Hygienic hose pumps from different manufacturers such as Abaque, Realax and Blue-White

Features of Food Grade Hose Pumps

Gentle Product Handling

- Low Shear Stress: The peristaltic action gently moves the fluid, minimizing shear stress on the product, making these pumps ideal for delicate fluids like live cultures, creams, and foams.

- Preserves Product Integrity: Peristaltic pumps can handle fragile, viscous, and particulate-laden products without causing separation or damage to the material's texture.

Self-Priming and Dry-Run Capable

- Self-Priming: Hygienic peristaltic pumps can prime themselves without the need for pre-filling the tubes, which simplifies operations and reduces downtime.

- Dry-Run Safe: These pumps can run dry without damage to the tubing, a key advantage in applications where fluid supply may be intermittent.

Material Construction

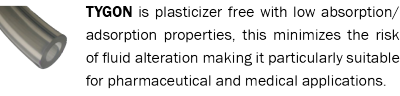

- Food-Grade Tubing: The tubing is made from FDA-approved, food-grade elastomers such as silicone or thermoplastic elastomers (TPE), ensuring compliance with industry standards for hygiene and safety.

- Corrosion-Resistant Housing: The pump housing is typically constructed from stainless steel or other sanitary materials to resist corrosion and allow for easy cleaning.

Performance and Efficiency

- Accurate Dosing: Peristaltic pumps are known for delivering precise flow rates, making them ideal for metering and dosing applications where accurate fluid delivery is critical.

- High Viscosity Capabilities: These pumps can handle fluids ranging from low to high viscosities, including thick syrups, creams, and pastes.

- Reversible Flow: Peristaltic pumps can operate in both directions, allowing for flexible fluid transfer and dosing applications.

Easy Maintenance and Cleanability

- Simple Tube Replacement: The flexible tubing is the only component in contact with the product, and it can be easily replaced, reducing downtime and simplifying maintenance.

- CIP/SIP Compatibility: Many hygienic peristaltic pumps are compatible with Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems, allowing for easy cleaning without the need to dismantle the pump.

- Minimal Wear and Tear: With no valves, seals, or impellers in contact with the fluid, wear and tear on the pump components is minimal, further reducing maintenance requirements.

Hose construction

![]()

Advantages of Hygienic Peristaltic Pumps

- Hygiene and Sanitation: With the fluid completely isolated in the tubing, peristaltic pumps are perfect for applications that require strict sanitary conditions.

- Versatile Fluid Handling: Capable of transferring liquids of varying viscosities and even those with suspended solids, hygienic peristaltic pumps offer a wide range of applications.

- Operational Flexibility: These pumps can handle fluids that might clog or damage other pump types, such as highly viscous, corrosive, or abrasive materials.

Hygienic Peristaltic Pump applications

- Hygiene and Sanitation: With the fluid completely isolated in the tubing, peristaltic pumps are perfect for applications that require strict sanitary conditions.

- Versatile Fluid Handling: Capable of transferring liquids of varying viscosities and even those with suspended solids, hygienic peristaltic pumps offer a wide range of applications.

- Operational Flexibility: These pumps can handle fluids that might clog or damage other pump types, such as highly viscous, corrosive, or abrasive materials.