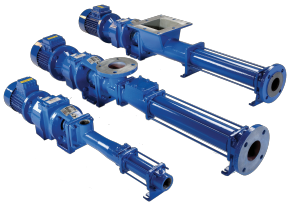

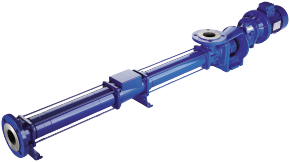

Industrial progressive cavity pumps

Progressive Cavity Pumps

4 series from 1 manufacturers

-

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Dredging

- Feed

- Filling

- Filtration

- Flow Control

- Handling

- High-Pressure

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Metering

- Mixing

- Off-loading

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Spraying

- Transfer

- Treatment

- Unloading

- Volumetric Dispensing

- Washing

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Aluminium Oxide Slurry

- Ammonia

- Beer

- Biological Broths and Slurries

- Bitumen

- Carbon Fibers

- Caustic Solutions

- Cereals

- China Clay Slurry

- Chocolate

- Clay

- Coffee

- Concrete

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Cryogenic Liquids

- Crystalline Slurry

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Fertilizers

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Viscosity Liquids

- Hydrochloric Acid

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Low NPSH

- Low Viscosity Liquids

- LPG

- Meat

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toxic Liquids

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

- Wine

- Wort

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Booster Sets

- Chemically Resistant

- Close-Coupled

- Compact

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Fish Friendly

- Flange

- Heavy-Duty

- High System Pressure

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Mechanical

- Mechanical Seal

- Multi-Stage

- Oil-Free

- Pulse-less

- Rotary

- Rugged

- Self-priming

- Single-Stage

- Solids Handling

- Variable Speed

- Vertical-Mount

The progressive cavity pump principle is ideal for handling liquids that can be slurries, viscous, shear sensitive, 2 or 3 phase mixtures or when applications require, significant suction lift capabilities.

The heart of the Progressive Cavity pump is the rotor and stator. As the shaft rotates, the rotor gradually forces fluid up the rubber stator. Such pumps can develop very high pressure at low volumes.