Chemical Pumps

Nearly every category of our chemical pumps are resistant to acids, alkaline solutions, and solvents. Because of our wide product range and expertise in the field of fluid transfer, we can offer chemical pumps to cope with the most corrosive of liquids and those with high and varying viscosities across the UK.

Some of the most common corrosive liquids handled by our chemical pumps are: caustic solutions, Ferric Chloride, Phosphoric Acid, Sulphuric Acid, Hydrochloric Acid, CIP fluids, corrosive dyes, radioactive fluids, Nitric Acid.

Types of Chemical Pumps AxFlow offer

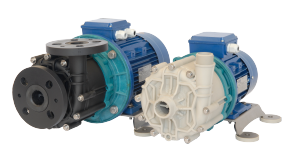

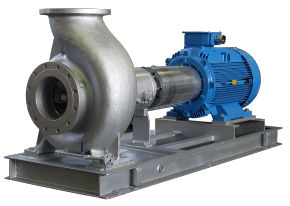

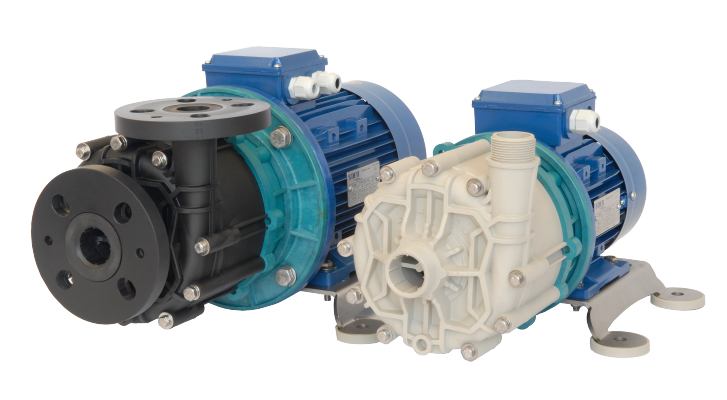

Wilden AOD pumps offer a cost effective and proven solution as chemical transfer pumps while our Almatec pumps over very high levels of product containment. Our centrifugal pump portfolio contains many ranges suitable for use as acid transfer pumps. This includes magnetic drive pumps, iso pumps, non metallic plastic pumps made from PP and PVDF, ETFE lined pumps, canned pumps all of which can be used a chemical transfer pumps.

Most or our OBL and Pulsafeeder metering pumps can be constructed from a range of chemically resistant materials and several offer high levels of product containment. All of our Realax peristaltic pumps can be used to pump acids and alkaline. The Mouvex C and SLS eccentric disc pumps are available in chemically resistant materials. They are useful as chemical pumps where dry priming is required. We have three ranges of chemically resistant vane pumps SNP, SVM and P Series.

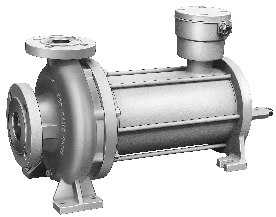

Our PTM range is available in polypropylene, PVDF and the STM range in stainless steel and other alloys to make our turbine process pumps ideal for pumping a range of aggressive chemicals where the flow is too low for centrifugal chemical transfer pumps.

WHY BUY CHEMICAL PUMPS FROM AXFLOW

- The largest range of chemical pumps in the UK

- Over 50 years of experience when it comes to chemical pumps

- Stocks of many of the most popular chemical pumps such as AODD and plastic mag drive pumps

- AxFlow supports is sales of chemical pumps from 5 technical pump centres spread across the UK

- We are expert pump repairers so know the practicalities of operating pumps and how they fail

Things to consider when selecting Chemical Pumps

-

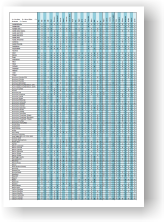

Chemical Compatibility: Corrosive fluids can react with certain materials thus resulting in chemical corrosion. Using Chemical pumps constructed from materials that are chemically compatible with the fluid being pumped helps prevent degradation of pump components and ensures long-term reliability.

-

Material Integrity: Corrosive fluids can compromise the structural integrity of pump components. If the pump materials are not corrosion resistant they may weaken, leading to leaks, fractures, or failure of the pump over time. Thus, resulting in an increase in maintenance costs.

-

Abrasion Resistance: Some corrosive fluids may also have abrasive properties, causing wear on pump components over time. Choosing materials that are resistant to both corrosion and abrasion ensures a longer lifespan for the pump and reduces the need for frequent replacements.

Applications for Chemical Pumps

AxFlow chemical pumps have been highly effective in handling challenging liquids, including abrasive fluids, various acids and other corrosive materials, flammables, inorganic solutions, liquids with entrained gases, slurries, solvents, toxic liquids, as well as viscous and volatile fluids.