Highly precision rotary lobe type pumps

Circumferential Piston Pumps

7 series from 1 manufacturers

-

- Biological Broths and Slurries

- Chocolate

- Dairy Products

- Emulsions

- Foam Protein

- Fruit Concentrates

- Gels

- Latex

- Milk

- Molasses and Syrups

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Pet Food

- Produced Water

- Rubber

- Sauces

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Soaps and Detergents

- Solids and Abrasives

- Surfactants

- Thixotropic Fluids

- Vegetable Oils

- Viscose

- Viscous Liquids

-

- Adjustable-Flow

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Flange

- Heavy-Duty

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- Low Shear

- Low-Noise

- Mechanical

- Mechanical Seal

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Self-priming

- SIP

- Solids Handling

- Variable Speed

- Vertical-Mount

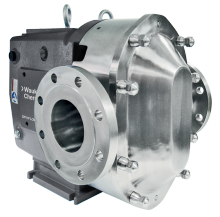

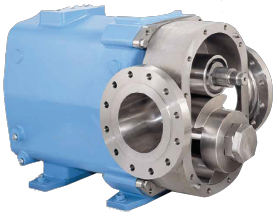

The Waukesha external circumferential piston pump (ECP) design, is superior to the typical lobe pump design as the long sealing path of the winged rotors reduce slippage and offers gentle handling of particulates. They also perform better with liquids which require gentle handling, low viscosity, and high viscosity or contain abrasives.

How Circumferential Piston (ECP) Pumps Work

Circumferential Piston (ECP) pumps are a type of positive displacement rotary pump designed to handle high-viscosity, shear-sensitive, and solids-laden fluids with precise, low-pulsation flow. They are widely used in food & beverage, pharmaceutical, chemical, and hygienic processing applications where gentle product handling and accurate dosing are critical.

Operating Principle

An ECP pump consists of a single rotating piston mounted eccentrically within a cylindrical casing. As the piston rotates, it maintains continuous contact with the pump casing, creating sealed pumping chambers that move fluid from the suction to the discharge side.

- On the suction side, increasing chamber volume creates a vacuum that draws fluid into the pump.

- As the piston rotates, the fluid is trapped in circumferential cavities formed between the piston and casing.

- On the discharge side, the chamber volume decreases, forcing fluid out at a controlled, uniform rate.

Because the piston maintains a tight clearance without metal-to-metal contact, the pump delivers smooth, low-shear flow with minimal internal slip.

Key Technical Characteristics

- Positive displacement operation: Flow rate is directly proportional to rotational speed.

- Low pulsation: Continuous chamber formation provides near-constant flow.

- High suction capability: Excellent performance with viscous or air-entrained fluids.

- Reversible flow: Pump direction can be reversed without modification.

- High efficiency at variable viscosities: Maintains performance where centrifugal pumps lose efficiency.

Materials and Hygienic Design

Circumferential piston pumps are commonly manufactured from stainless steel with elastomer or polymer pistons, allowing compatibility with CIP/SIP cleaning, aggressive chemicals, and temperature-sensitive products. Large internal clearances and gentle flow paths enable safe handling of soft solids without product damage.

Typical Applications

- Food and beverage transfer and dosing

- Pharmaceutical and biotechnology processes

- Cosmetics and personal care products

- Chemical and polymer handling

Advantages of External Circumferential Piston Pumps:

The long sealing path reduces slippage and produces a smooth flow of product without destructive pulses or pressure peaks, and without valves or complex parts.

The wide orifices and large fluid cavity allow ECP pumps to handle large solids and abrasive liquids. The combination of these features means that ECP pumps offer a gentle pumping action with reduced risks of burning sensitive liquids.

ECP pumps have timing gears that are locked with key & keyways as are the rotors which eliminates the risk of timing gears slipping. The added advantage being no requirement for tricky re-timing the rotors following maintenance procedure.

- No slippage on product over 200 cP.

- an extremely gentle and smooth pumping action,

- the ability to handle viscous fluids of up to 200,000 cP,

- No galling or seizing.

- An increased priming capability.

- Higher pressure capabilities.

- No product ingress between rotor face and rotor case.

Why buy ECP pumps from AxFlow?

AxFlow have over 40 years’ experience with ECP pumps and throughout this time have been associated with the technology leading Waukesha Universal range of products. The Universal suite of ECP pumps is comprised of 5 separate ranges covering a wide performance range, seal types and constructions; this allows Axflow to offer the best technical and cost effective solution.

In addition to this Waukesha Universal ECP pumps have rotor wings manufactured to extremely close tolerances from non-galling Alloy W88 and are designed with no cavity between the rotors, as is the case with rotary lobe pumps, to allow the passage of fluid.

The way Waukesha ECP pumps are manufactured allows them to be refurbished using oversized rotors and slightly enlarged chambers to prolong their service life and do not suffer from the problem of timing slip as can often be experienced with rotary lobe pumps

AxFlow are experts at refurbishing ECP pumps from our technical pump repair centres spread across the UK.

- AxFlow holds over 1,600 lobe & ECP pumps in stock which allows us to offer a reliable delivery on bare-shaft pumps of 2-3 days and new pump-sets of under 3 weeks.

- To support our pumps in the field, AxFlow holds over 128,152 spare hygienic pump components and kits in stock available on a standard 2-3 or express 24-hour delivery.

|

|

Type |

FDA |

EHEDG |

3-A |

ATEX |

Max Flow m3/hr |

Max bar |

Max Viscosity |

Seal Options |

|

Hygienic ECP |

● |

● |

● |

● |

102 |

13 |

200K cP |

Lip |

|

|

Hygienic ECP |

● |

● |

● |

● |

150 |

13.8 |

200K cP |

Mech |

|

|

Hygienic ECP |

● |

● |

● |

● |

102 |

34.5 |

200K cP |

Lip/Mech |

|

|

Hygienic ECP |

● |

|

● |

● |

187 |

13.8 |

200K cP |

Very Low |

|

|

ECP |

● |

|

|

|

102 |

13.8 bar |

50k cP |

Mech/Packing |

|

|

Hygienic ECP |

● |

● |

● |

● |

68 |

17.2 |

1 million cP |

Mech |

How to Select a Circumferential Piston (ECP) Pump

Selecting the correct Circumferential Piston (ECP) pump is critical for achieving reliable, low-shear, and accurate fluid transfer in hygienic and industrial process applications. Proper selection ensures optimal performance, long service life, and reduced lifecycle costs.

Key Selection Criteria

Flow and Pressure

- Flow rate: As a positive displacement pump, ECP pump flow is directly proportional to rotational speed. Select pump size to meet required throughput with adequate turndown.

- Differential pressure: Ensure the pump is rated for maximum operating pressure, including viscosity-related load increases.

Fluid Properties

- Viscosity: Suitable for low to high-viscosity fluids without significant efficiency loss.

- Shear sensitivity: Ideal for shear-sensitive products due to smooth, low-pulsation flow.

- Solids content: Capable of handling fluids containing soft solids without product damage.

- Temperature and chemistry: Select wetted materials and elastomers compatible with process and cleaning conditions.

Hygienic and Mechanical Design

- CIP/SIP compatibility and hygienic surface finishes where required.

- Sealing systems: Single or double mechanical seals matched to pressure and product type.

- Piston materials: Elastomer or polymer pistons selected for wear and chemical resistance.

- Drive control: Use VFDs for precise flow control and gentle start-up.

- Reversible operation: Enables product recovery and line emptying.

Circumferential Piston (ECP) Pump Maintenance

Proper Circumferential Piston (ECP) pump maintenance is essential to preserve low-shear performance, maintain volumetric efficiency, and ensure hygienic integrity in demanding process applications. A structured maintenance approach reduces wear, prevents leakage, and extends service life.

Key Maintenance Practices

Routine Inspection and Monitoring

- Inspect for leakage at mechanical seals, O-rings, and casing joints

- Monitor noise, vibration, and drive load, which may indicate piston wear or misalignment

- Verify stable flow rate and discharge pressure to confirm consistent volumetric performance

Piston, Casing, and Clearances

- Inspect the circumferential piston for wear, deformation, or chemical attack

- Check internal clearances between piston and casing to prevent slip and efficiency loss

- Replace pistons showing excessive wear to maintain sealing integrity

Seals and Hygienic Components

- Inspect mechanical seal faces and elastomers for wear or swelling

- Ensure seal materials remain compatible with product chemistry and temperature

- Verify CIP/SIP systems are operating correctly and free from blockages

Bearings, Drive, and Alignment

- Lubricate bearings according to manufacturer specifications

- Check shaft alignment and coupling condition to prevent premature wear

- Avoid continuous operation at excessively low speeds unless specified

Planned Maintenance and Storage

- Schedule inspections based on operating hours, pressure, and product abrasiveness

- Replace wear components before efficiency or hygienic performance is compromised

- For extended shutdowns, clean thoroughly, dry internal surfaces, and protect elastomers from chemical exposure

Read more information on Circumferential piston pump fault diagnosis