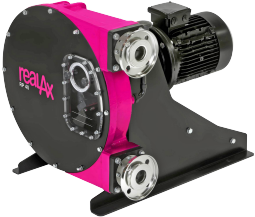

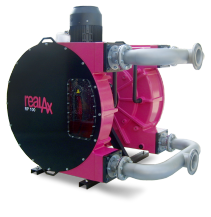

A peristaltic pump works by pressure and displacement. It is used mainly to pump liquids, yet even with solids, through a hose or tube. Hence no parts of the pump come into a contact with the pumped liquid.

Peristaltic Pumps

15 series from 3 manufacturers

-

- Acetate

- Adhesives

- Agriculture

- Bakery and confectionery

- Beauty & Personal Care

- Brewing and beverages

- Building Services

- Ceramics

- Chemical

- Convenience food

- Dairy

- Detergents

- Distilleries

- Docks

- Drinking Water

- Dye & Pigment

- Emulsions

- Fertilizers

- Fish Farming

- Food & Beverage

- Fruit Concentrates

- Heating, Water & Sanitation

- Marine

- Meat Processing

- Mining

- Oil & Gas

- Oil Fats & Mayonnaise

- Paint & Surface Coating

- Paints & Resins

- Paper Mills

- Pet Food

- Petrochemical

- Pharmaceutical

- Plastic

- Power Generation

- Research & Development

- Sugar Processing

- Surface Finishing

- Textile

- Wastewater

- Water Treatment

-

- Analysis

- Booster

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Dosing

- Drain

- Drainage

- Dual Dispensing

- Extraction

- Feed

- Filling

- Filtration

- Flow Control

- Greasing

- Handling

- Heating

- High-Temperature

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Metering

- Mixing

- Off-loading

- Powder Coating

- Process

- Processing

- Recirculation

- Recovery

- Replacement

- Rinsing

- Sampling

- Settling

- Tempering

- Transfer

- Treatment

- Unloading

- Washing

- Water-Jet Cleaning

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Aluminium Oxide Slurry

- Ammonia

- Beer

- Biological Broths and Slurries

- Bitumen

- Carbon Fibers

- Caustic Solutions

- Cereals

- China Clay Slurry

- CIP Fluids

- Clay

- Coffee

- Concrete

- Corrosive Dyes

- Corrosive Liquids

- Crystalline Slurry

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Foam Protein

- Fruit Concentrates

- Gels

- Glycol

- High Viscosity Liquids

- Hydrochloric Acid

- Hygienic Liquids

- Latex

- Light Fluids

- Lime

- Low NPSH

- Low Viscosity Liquids

- Milk

- Molasses and Syrups

- Non-Newtonian Fluids

- Paints

- Paints Resins

- Personal Care Products

- Phosphoric Acid

- Produced Water

- Redox

- Seawater

- Sensitive and Viscous Fluids

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thin Liquids

- Thixotropic Fluids

- Toxic Liquids

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

- Wine

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Corrosion-Proof

- Direct-Drive

- Double-Acting

- Electric

- Explosion-Proof

- Fish Friendly

- Flange

- Heavy-Duty

- High Temperature

- High-Efficiency

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Mechanical

- Mixed Flow

- Mobile

- Modular

- Motorless

- Non-Metal

- Oil-Free

- Pneumatic

- Rotary

- Rugged

- Sanitary

- Seal-less

- Self-priming

- Single-Stage

- SIP

- Solids Handling

- Variable Speed

This is the major difference and design advantage compared to other positive displacement pump types.

The simplicity of the hose pump provides a number of advantages. The hose can be made from any of a variety of materials.

More about the working principle

The pump rotor exerts pressure on a set of rollers or shoes which compress the hose. This forms a vacuum drawing fluid into the hose while the next roller or shoe gently pushes the fluid forward. Pump wear is limited virtually to the hose which is quick and inexpensive to replace.