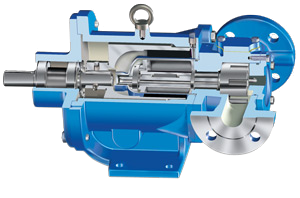

Viking Internal Gear Viking Mag Drive

Category: Pumps

SubCategory: InternalGearPumps

Manufacturer: Viking

Industry: BeautyPersonalCare;MechanicalEngineering;OilGas;BuildingServices;FoodBeverage;Chemical;Petrochemical;AdhesivesProduction;Agriculture;HeatingWaterSanitation;DetergentProduction;NuclearPowerPlants;DyePigmentProduction;EmulsionProduction;BakeryConfectionery;PowerGeneration;WaterTreatment

SubCategory: InternalGearPumps

Manufacturer: Viking

Industry: BeautyPersonalCare;MechanicalEngineering;OilGas;BuildingServices;FoodBeverage;Chemical;Petrochemical;AdhesivesProduction;Agriculture;HeatingWaterSanitation;DetergentProduction;NuclearPowerPlants;DyePigmentProduction;EmulsionProduction;BakeryConfectionery;PowerGeneration;WaterTreatment

Sealless Pumps for Crucial Liquid Containment Applications

Key Specifications

- Flows up to 132 m³/h

- Pressure up to 17 bar

Product features

- Multiple port sizes, types and ratings available, including threaded, raised, and flat-face flanged

- Jacketing options available for critical areas of pumps, including the casing, head and relief valve

- Materials of construction: steel, stainless steel, and cast iron

Product description

The internal gear pumping principle was invented by Jens Nielsen, one of the founders of Viking Pump. It uses two rotating gears which un-mesh at the suction side of the pump to create voids which allow atmospheric pressure to force fluid into the pump. The spaces between the gear teeth transport the fluid on either side of a crescent to the discharge side, and then the gears re-mesh to discharge the fluid. Viking's internal gear design has an outer drive gear (rotor- shown in orange) which turns the inner, driven gear (idler-shown in white).