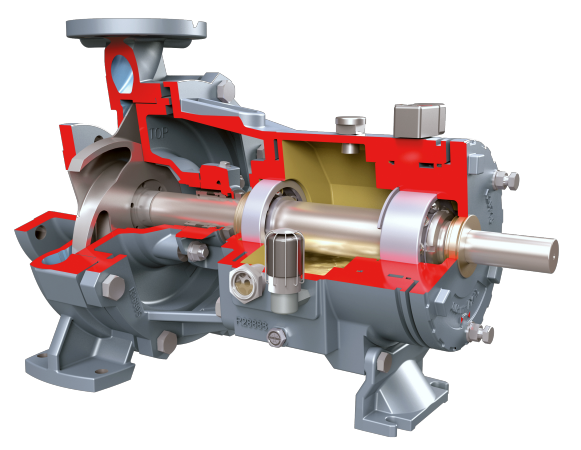

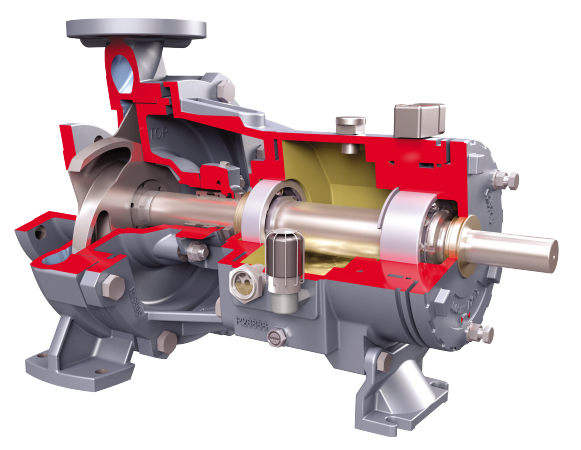

Flowserve Durco Mark 3 ISO

SubCategory: CentrifugalPumps

Manufacturer: Flowserve

Industry: Chemical;FoodBeverage;Mining;OilGas;PaperMills;Pharmaceutical;PowerGeneration;WaterTreatment

Key specifications

- Flows up to 1400 m³/h

- Pressure up to 25 bar

Product features

- Flows to 1400 m3/h

- Heads to 220 m

- Pressures to 25 bar

- Temperatures from -80°C to 400°C

- High efficiency design with low power consumption

- Modular system resulting in maximum flexibility to adapt to a wide variety of applications

- Heavy-duty casing, radial and trust bearings

- SealSentry™ seal chamber extends seal life and provides advanced self-flushing capability

- Standards ISO 2858, ISO 5199, ATEX (2014/34/EU)

Description

The Durco Mark 3 ISO pump line is available in four frames with 45 sizes to accommodate virtually all process flow requirements. Configurations include open or reverse vane impeller designs, recessed impeller and unitized self-priming models and close coupled arrangements. An extensive range of materials is available to address the issues of corrosion and erosion commonly found in chemical processing.

All Mark 3 ISO pumps are equipped with the IPS Beacon™ power end condition monitor. Mounted on top of the bearing housing, this is an electronic device that continuously monitors the vibration and temperature levels of the bearings, providing a visual indication when set operating limits are exceeded.