FLUX Container pump MINIFLUX

Category: Pumps

SubCategory: DrumPumps

Manufacturer: Flux

Industry: AdhesivesProduction;Agriculture;Chemical;DrinkingWaterTreatment;PaintSurfaceCoating;Petrochemical;SurfaceFinishing

SubCategory: DrumPumps

Manufacturer: Flux

Industry: AdhesivesProduction;Agriculture;Chemical;DrinkingWaterTreatment;PaintSurfaceCoating;Petrochemical;SurfaceFinishing

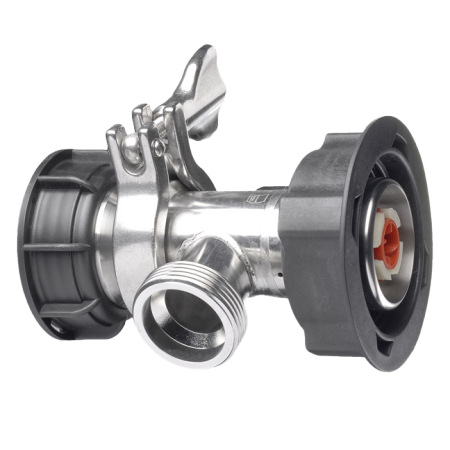

The horizontally installed, compact container pump MINIFLUX is designed for emptying IBCs via their floor-level outlet. Designed as an alternative to a vertical pump, the MINIFLUX can be used when an IBC is not accessible from the top.

Key specifications

- Flows up to 240 l/min

User benefits

- Can be used where ceilings are low

- Allows pumping directly from floor-level outlets, even when containers are stacked

- Significantly higher flow rate and pressure compared to draining by gravity

- Suitable for use in hazardous areas zone 1

Product features

- For pumping out of IBCs directly from the outlet (with standard S60 x 6 thread)

- Simple connection of the pump to the outlet by union nut

- Compact design

- Can be dismantled into two parts via clamp

Description

The MINIFLUX is suitable for applications when gravity draining via the outlet tap is insufficient e.g. rapid dispensing or transfer to another container in a higher location. Power can ideally be provided by a commutator or compressed air motor. The FLUX drum pumps operate on the principle of the axial-impeller pumps. The pump unit consists of drive motor and pump. The motor drives the drive shaft via a coupling. At the end of the drive shaft there is a propeller-like pump impeller (rotor). The rotor must be completely covered with the medium that the pump can work. With the rotation the medium is axially transferred to the outlet, i.e. parallel to the pump shaft.