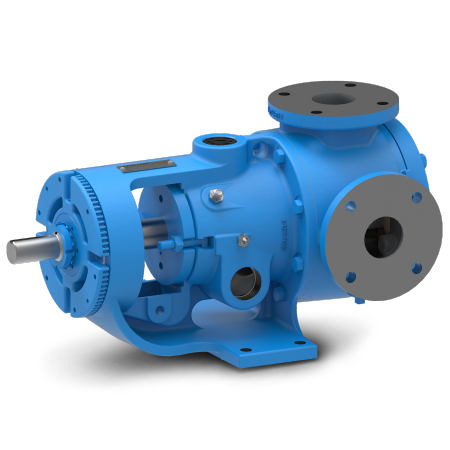

Viking Pump for Sugar Processing

Category: Pumps

SubCategory: InternalGearPumps

Manufacturer: Viking

Industry: FoodBeverage;SugarProcessing

SubCategory: InternalGearPumps

Manufacturer: Viking

Industry: FoodBeverage;SugarProcessing

Optimum and constant product quality through gentle conveying - a gear pump specially designed for processing raw sugar

+

Key specifications

- Flows up to 202 m³/h

- Pressure up to 14 bar

Description

Viking's internal gear pumps are used throughout the process of refining raw sugar into finished sugar and liquid products. Applications include syrup, magma, massecuite, molasses, liquid sugar and invert sugar.

In order to further increase the service life of the pumps and to ensure even gentler conveying of the sugar crystals, Viking has developed a special rotor. The gradations on the rotor ensure that the sugar crystals are conveyed with minimum mechanical stress and that they are largely prevented from being destroyed.

Holes on the rotor improve flushing, reduce friction and prevent heat build-up and caramelization on the bearings.