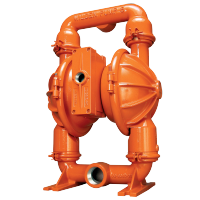

Wilden Powder Pump

Wilden® Pneumatic Powder Transfer Diaphragm Pump

Safe, Reliable, Efficient

Wilden Powder Transfer Diaphragms are ideally suited for conveying light, dry, and non-adhesive industrial powders, including carbon black, silica dust, silicone, resins, and pharmaceutical powders. To ensure effective and safe transport, it is recommended that the powder’s bulk density should not exceed 800 kilograms per cubic meter, and the particle size of the powder is recommended not to be larger than 150 micrometers.

Wilden Powder Transfer Diaphragms are ideally suited for conveying light, dry, and non-adhesive industrial powders, including carbon black, silica dust, silicone, resins, and pharmaceutical powders. To ensure effective and safe transport, it is recommended that the powder’s bulk density should not exceed 800 kilograms per cubic meter, and the particle size of the powder is recommended not to be larger than 150 micrometers.

Wilden powder pumps are currently available in 2 inch and 3 inch sizes in both aluminum alloy and stainless steel, with diaphragms recommended in Santoprene, with options for half-stroke PTFE and Viton.

The maximum inlet pressure for the main air source is 8.6bar; for the fluidizing air, the maximum inlet pressure is 6.9bar,recommended not to be less than 2bar.

Benefits

Safety

- Operates on pneumatic power, eliminating the risk of electrical spark generation.

- The pump’s operation generates no heat, complying with dust explosion-proof standards.

- Features a fully-sealed powder transfer system that conveys materials directly from the source container to the processing receptacle, minimizing workplace dust contamination and safeguarding personnel health.

Reliability

- The one-touch blowback feature effectively clears powder accumulation around the valve balls, reducing resistance during pump start-up.

- Synchronous and efficient airflow induction fluidization technology optimizes the ratio of material to gas. This prevents powder accumulation while reducing gas consumption and the gas content in the material.

- The fluidizing air that contacts the powder is purified and dried through a cyclone air-water separator, reducing the impact of atmospheric moisture on the powdered materials.

- The unbalanced air valve design eliminates stalling during pump operation.

Efficiency

- Replaces inefficient manual powder conveying methods.