Wipe out the wipes problem......with Mono Munchers and screens

Disposing of wet wipes in the toilet is causing water plants major problems and increases cost.

Treatment plants fulfill an important function in society to prevent the spread of infection and eutrophication but have major challenges with what is flushed down the toilet. Anything other than toilet paper causes problems. Toilet paper dissolves quickly in water, but other solid materials such as wet wipes, cotton and tampons do not. Instead, they form long threads and twist together, causing blockages and damage to pumps. Even hair causes serious problems with blockages. We have also read about the fat monster in London’s sewer system.

Use is increasing - so is cost

Wet wipes are more and more popular, commonly used for sanitary use, face wash and house cleaning. When flushed down the toilet, these wipes cause major problems for the sewage treatment plant. We’ve seen on the news lately how huge amounts of wet wipes are escaping treatment plants. Many water treatment plants have experienced problems with clogged pumps due to buildup of wet wipes.Pumping stations in municipalities have major problems with frequently occurring blockages in their large sewage pumps. Almost every day, several hours of work with dismantling, taking apart and cleaning the pumps. Maintenance costs are high, and it is a dirty and time-consuming job.The additional cost of a water treatment plant due to this problem can be very high per year.

The solution spells Munchers from Mono

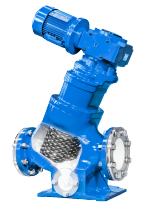

We offer you the solution with Mono Munchers! The Muncher cuts the waste into small pieces so that it does not cause any damage to your valuable equipment. With its special design for atomizing abrasive sludge, the TR Muncher is very effective in capturing irregularly shaped particles. It finely shreds, for example, rags, solid impurities, and fiber accumulations in treatment plants and pumping stations.

We keep your processes running

By using a Muncher, the need for operational interruptions due to cleaning the pump and grid is minimized. In the Muncher’s housing, there are two shafts mounted with cutting knives that are driven against each other to grab hold of the solid impurities.With the TR Muncher range, the entire cutter stack can be removed from the housing as a cartridge, without needing to disconnect the unit from the pipework. In the case of the CT201 the cutters can also be inspected and removed through the front cover. All units in the TR Muncher series operate at slow speeds, resulting in lower energy consumption, vibration, and noise than macerators operating at high speeds. Don’t feed the treatment plant monster!