For Production- and Technical Engineers

AxFlow's "System Thinking" pays off if you plan to install new systems or evaluate performance with existing ones.

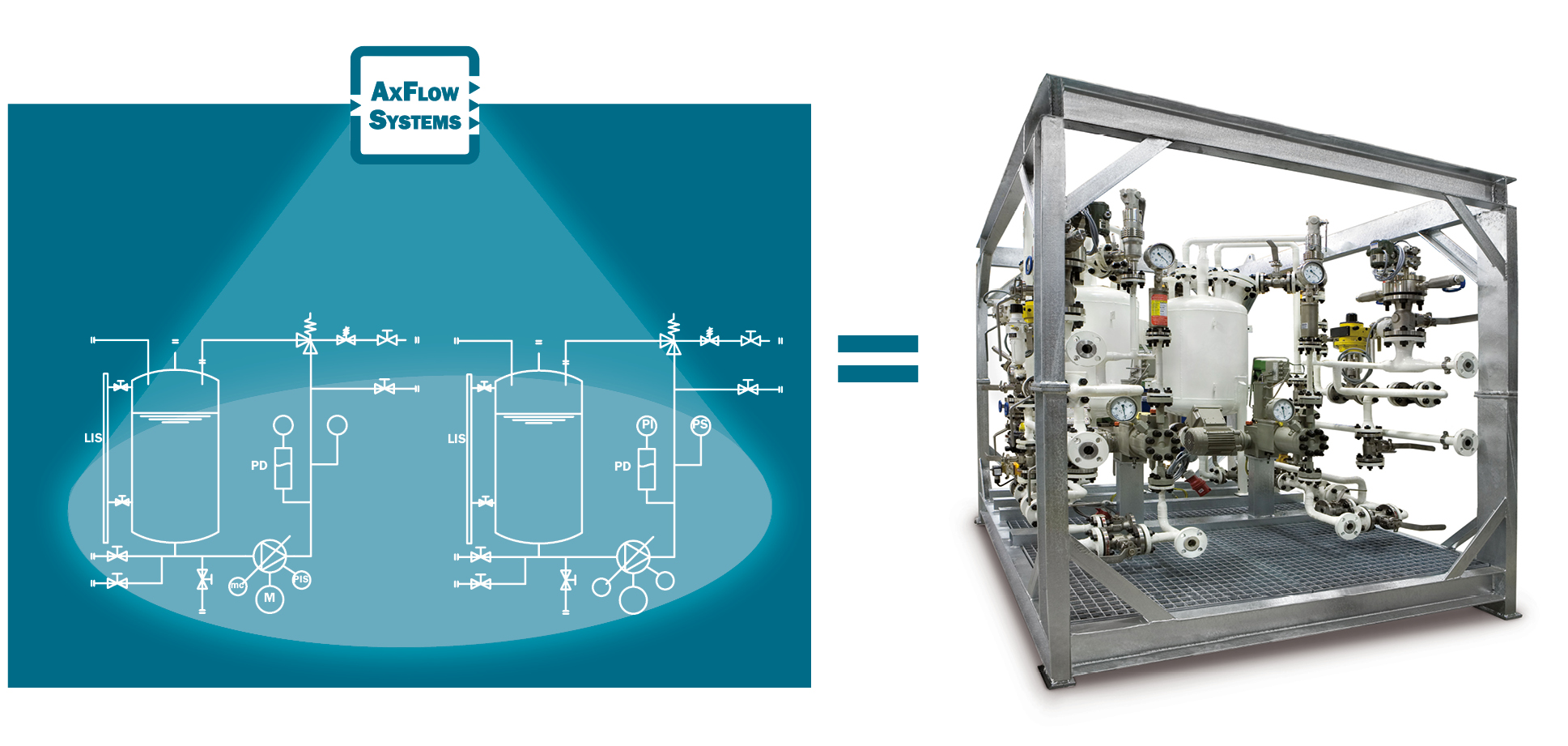

EXAMPLE OF OUR SYSTEMS CAPABILITIES: A chemical dosing skid manufactured using a galvanized box frame comprising two additive storage tanks and metering pumps with a capacity of 150 l/h at 23 bar. These feature pneumatically-actuated stroke length control. There is an integrated leakage bin with a floor grating, piping, pulsation dampeners, flow meters, pressure sustaining and relief valves, isolation and flush valves and controls. The system offers 100% redundancy.

Think generously. Think even more generously.

With existing processes that have often undergone several rebuilds, we can find risk errors, incompatibilities with devices, and their suboptimal use. Based on this analysis, we will design a proposal for the optimization of a certain part of the production operation, including the design and delivery of new equipment - such as a new dosage unit. This approach is beneficial both in terms of total optimization of production operations and also for possible savings in the form of lower product losses, optimal energy use, minimal downtime, faster cleaning and thus shorter operating shutdowns. Why? Because we deal with things in the context, from A to Z.

Solid long-term investment

Our systems are designed and installed to be fully compatible with your production operations. We work to keep your traffic as smooth as possible, with minimal operating time and wear on individual units. Complete design, project preparation, assembly, and installation services - from a single, reliable supplier - guarantee a safe, reliable and cost-effective improvement of your process.

BENEFITS FOR YOUR OPERATIONS:

- Enhanced process output

- Less frequent interruptions

- More thorough cleaning and maintenance

- Lower product loss

- Higher production flexibility

- Optimized energy consumption

- Purpose-designed, purpose-built

- Pre-tested, installed and commissioned

- Totally compatible with the rest of our process