Challenges in Pumping Thermal Service Fluids

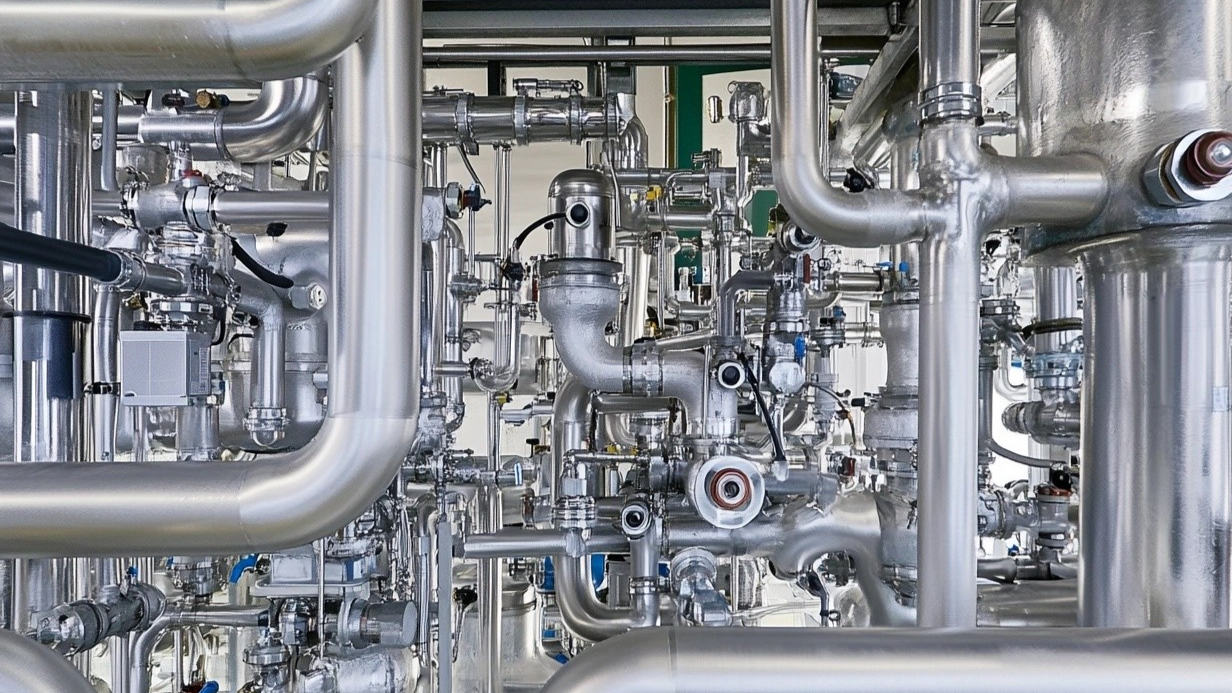

Pumping thermal service fluids, encompassing both extreme heat and cold, presents intricate challenges that demand careful consideration and specialized equipment. These fluids, crucial in various industrial processes, require precise handling to maintain their properties. AxFlow recognizes the complexities involved and offers tailored solutions to ensure efficient and reliable pumping, even in extreme temperature conditions.

- Wide Temperature Range: Thermal service fluids cover a broad temperature spectrum, from -150°C to 450°C. Handling these diverse temperatures demands pumps capable of withstanding extreme heat or cold without compromising efficiency.

- Cavitation Risks: Pumping hot liquids near their boiling point can lead to cavitation, a phenomenon where vapor bubbles form and collapse, causing damage. Adequate pressure is crucial to preventing cavitation, ensuring the liquid remains in a stable state.

- Seal Flashing: Hot liquids can cause seal flashing, leading to wear and reduced pump efficiency. Cooling techniques and specialized pump designs, creating higher pressure around the seal, are essential to counter this issue.

- Similar Challenges for Cold Liquids: Pumping cold liquids poses challenges akin to hot liquids. Cavitation remains a concern due to the thin consistency and low boiling points of many refrigerants. Additionally, lubrication problems and off-gassing can occur if pumps with mechanical seals are employed.

Handling Thermal Service Fluids

- Magnetic Drive and Canned Pumps: For hot liquid applications, magnetic drive and canned pumps emerge as the safest and most reliable options. These pumps encapsulate the liquid, eliminating seal flashing issues and ensuring efficient transfer even at high temperatures.

- Pressure Control: Proper pressure regulation is critical for preventing cavitation in both hot and cold thermal service fluids. Advanced pump designs with precise pressure control mechanisms help maintain stable flow and prevent damage.

- Material Compatibility: Selecting pump materials compatible with the specific thermal service fluid is paramount. AxFlow offers a range of corrosion-resistant materials, ensuring durability and longevity, even in extreme temperature conditions.

Examples of Thermal Service Fluids

- Heat Transfer Oils: Used in industrial heating and cooling systems, ensuring uniform temperature distribution in various processes.

- Refrigerants: Employed in refrigeration and air conditioning systems to maintain low temperatures, crucial for food storage and climate control.

- Molten Salts: Utilized in solar power plants and industrial applications for energy storage and heat transfer.

Thermal Service Fluids Applications

- Power Generation: Thermal fluids play a vital role in power plants, enabling efficient heat exchange and energy production.

- Chemical Processing: Used in chemical reactors and distillation processes, ensuring precise temperature control and efficient reactions.

- HVAC Systems: Thermal service fluids are integral to heating, ventilation, and air conditioning systems, maintaining comfortable indoor environments.

The successful pumping of thermal service fluids demands specialized pumps capable of handling extreme temperatures, preventing cavitation, and ensuring efficient transfer. AxFlow's expertise, coupled with a wide range of pump options, guarantees optimal performance, reliability, and safety in thermal service fluid applications, setting new standards in industrial efficiency and productivity.