Products:

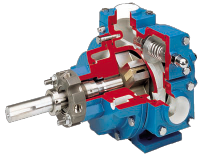

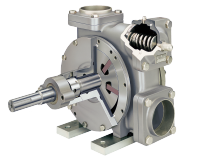

Blackmer NP and SNP sliding vane pumps. Choose your country above to read more about products for this industry.

Industry:

Petroleum product processing.

Challenge:

To transfer a range of viscous, shear sensitive bitumen emulsion products from bulk holding tanks to road tankers at temperatures of up to 260oC.

Solution

Blackmer NP and SNP vane pumps were used as they are capable of delivering flows of up to 200 m3/hr, offer a low shear pumping action, can handle viscous liquids and deliver high discharge pressures.

Blackmer sliding vane pumps feature vanes that slide out of slots in the pump rotor as a result of centrifugal forces, push rods and the internal pressure from the fluid being pumped.

Using this combination of methods means that Blackmer vane pumps can run at slow speeds enabling them to handle viscous fluids while subjecting them to very little disturbance; both important characteristics when it comes to the transfer of bitumen emulsions.

In addition the vane pumps can be reversed for short periods allowing the pipeline work to be cleared and the liquid to be transferred back into the feed tanks, thereby reducing the possibility of product cross-over.

The pumps were also fitted with steam quenched seals that both maintained the temperature of the bitumen and protected the seals from seizing.

As positive displacement pumps and the push rods that maintain the pressure of the vanes against the pump housing, the volume transferred by the Blackmer vane pumps remains consistent irrespective of the viscosity of the bitumen and for the life of the pumps.