In its liquid state, it is abrasive and is difficult to pump due to the high solids content and can also cause considerable wear. In order to prevent the solids settling in the pump housing, a continuous pumping action is required to ensure that all the liquid is kept in motion and the solids in suspension. This also helps to reduce wear on the pump internals.

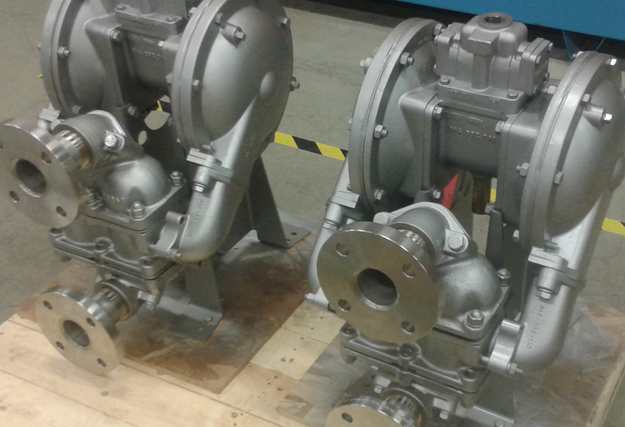

When approached by a leading manufacturer of speciality chemicals in The Netherlands to recommend pumps for handling aluminium slurry, AxFlow’s recommendation was to select air-operated double diaphragm pumps, and specifically the Sandpiper HDB model. The pumps are used to transfer the slurry from the buffer tank to the reactor.

Several factors pointed to this as being the best solution. Firstly, compared to other pumps types it was a relatively low-cost purchase, made even more attractive because it did not require additional instrumentation or a control panel. However, more importantly the Sandpiper HDB is a robust, heavy duty ball valve pump that can deliver a slow flow rate without solids settling in the pump chamber, because it employs a down ported discharge port. Fitted with pulsation dampeners, these pumps deliver a smooth, pulsation-free flow.

Sandpiper HDB metallic Heavy Duty ball valve pumps are ideal for thin to highly viscous and small solids-laden liquids. Offering a choice of top, side and bottom discharge porting options, they provide excellent suction lift capability. The down ported discharge port is positioned below the centre of the pump so solids do not settle in the pump chamber but in the elbow from where they are easily discharged. A major benefit of this pump type is the weighted check balls which are between 30 and 60 per cent heavier than solid rubber check balls. Their metallic cores provide the additional weight that helps to improve performance. This is because the greater mass provides more consistent chamber filling as it seats more quickly during operation, this in itself is a great advantage for pumping viscous products, and delivers a better seating load in flooded or suction conditions.

Positive displacement AODD pump technology has grown to become the leading choices for liquid handling and transfer in a wide variety of industries. Sandpiper AODD pumps are able to satisfy the various demands of the industry because their design provides a broad range of configurations: standard, containment duty, heavy duty flap valve and heavy duty ball valve. Other benefits of this pump technology include its ability to be used in a wide range of pressure and flow specifications, self-priming and low-shear operation; ability to handle corrosive and abrasive solutions; improved energy efficiency; and overall low maintenance costs.

Sandpiper HDB pumps have been developed to operate in harsh conditions where hazardous media require safe handling. With these pumps additional safety valves are not required, a factor that gives the benefits of easy installation where compressed air supply is readily available and a lower initial purchase price when compared to other more complex pump types. What cannot be ignored is that the Sandpiper can offer the best solution due to the comprehensive range of models developed specifically to accommodate many different applications.