Unloading and precise additives injection before crushing

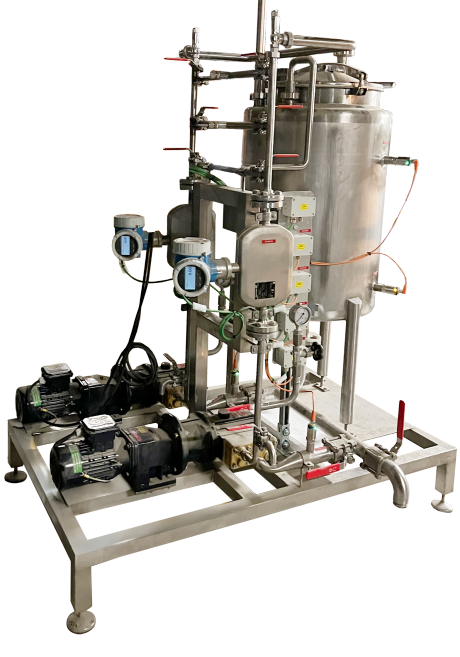

A complete additive management system, from unloading from the tanker into storage tanks precise and monitored additive injection.

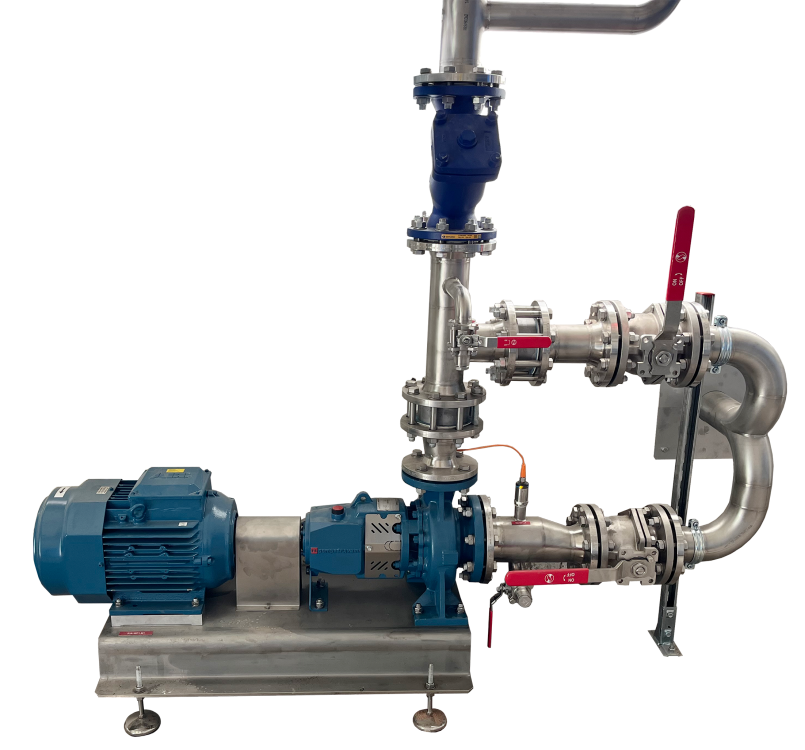

A powerful Pompetravaini centrifugal pump ensures the unloading of the additive from a 30m3 tank into three interconnected storage tanks, which are monitored by radar sensors. From these large tanks, the additive is automatically filled into a small 200l tank of the dosing unit and then injected onto one or two production belts, along which the stony material moves into the mill. A constant and precise injection rate is monitored by a combination of a Wanner HydraCell-G dosing pump and mass flow meters. The correct injection rate ensures significant energy savings during the crushing process.

SYSTEM PARAMETERS

- Flow rate: 10 - 100 l/h

- Pressure: 2 bar

- Accuracy: 1-2%

- Medium: additives (glycol)

- Medium concentration: 100%

- Medium temperature: 5-40°C

- Viscosity: 1-100 cP

- Tank capacity: 200 l

- Height: 2 m

- Footprint: 1,8 x 1,8 m

- Weight: 200 kg

- Materials: Stainless steel 316L, brass

- Certifications: CE

Used components:

Wanner Hydra-Cell G

Pompetravaini TCH

Features:

- Fully automatic stock monitoring process on the ground floor

- Minimal maintenance thanks to sealless pump design

- Option to connect an additional IBC with experimental additive for property testing