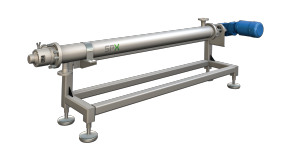

Scraped surface heat exchangers (SSHEs) operate through forced convection and scraping. They consist of a cylindrical vessel with a rotating inner tube, called a rotor, that scrapes the surface of the heat transfer wall as it rotates. The rotor has blades that sweep the product from the wall and create a turbulent flow, which increases the heat transfer rate. These heat exchangers are ideal for processing high viscosity products and are used in various industries such as food, chemical, pharmaceutical, cosmetic, personal care, and pet food. When selecting a scraped surface heat exchanger, several factors need to be considered, such as viscosity, particle size, temperature, flow rate, and cleaning. AxFlow offers scraped surface exchangers for various industries and applications, providing individual advice from industry-experienced process engineers and the manufacturer-independent selection of the world's leading process technology.

Scraped Surface Heat Exchangers

2 series from 2 manufacturers

-

- Analysis

- Circulation

- Cleaning

- Control

- Conveying

- Cooling

- Descaling

- Desinfection

- Dewatering

- Diagnostic

- Discharge

- Distribution

- Drain

- Drainage

- Dual Dispensing

- Feed

- Filling

- Filtration

- Flow Control

- Greasing

- Grinding

- Handling

- Heating

- High-Pressure

- High-Temperature

- High-Volume

- Injection

- Irrigation

- Level Control

- Lift

- Lifting

- Loading

- Low-Pressure

- Lubrication

- Medium-Pressure

- Mixing

- Off-loading

- Powder Coating

- Pressurisation

- Process

- Processing

- Recirculation

- Recovery

- Refueling

- Replacement

- Rinsing

- Sampling

- Settling

- Spraying

- Tempering

- Transfer

- Treatment

- Unloading

- Volumetric Dispensing

- Washing

- Water-Jet Cleaning

-

- Abrasive Liquids

- Acetate

- Acids

- Adhesives

- Alcohols

- Ammonia

- Beer

- Bitumen

- Carbon Fibers

- Caustic Solutions

- Cereals

- China Clay Slurry

- Chocolate

- CIP Fluids

- Clay

- Coffee

- Concrete

- Cooling Water

- Corrosive Dyes

- Corrosive Liquids

- Dairy Products

- Detergents

- Diesel Fuel Oil

- Drinking Water

- Dye Pigment

- Emulsions

- Ethylene Glycol

- Ferric Chloride

- Fertilizers

- Foam Protein

- Fruit and Vegetables

- Fruit Concentrates

- Gels

- Glycol

- High Temperature Oils

- High Viscosity Liquids

- HydrochloricAcid

- Hygienic Liquids

- Irrigation Water

- Lake Water

- Latex

- Light Fluids

- Lime

- Liquid CO2

- Low NPSH

- Low Viscosity Liquids

- LPG

- Meat

- Milk

- Molasses and Syrups

- Must

- Non-Newtonian Fluids

- Oil, Fats and Mayonnaise

- Paints

- Paints Resins

- Personal Care Products

- Pet Food

- Phosphoric Acid

- Plastic

- Process Condensate

- Produced Water

- Radio Active Fluids

- Redox

- Refrigerants

- Rubber

- Sauces

- Seawater

- Sensitive and Viscous Fluids

- Separated Oil Processing

- Sewage

- Silver Nitrate

- Soaps and Detergents

- Solids and Abrasives

- Solvents

- Spirits

- Sulphuric Acids

- Surface Water

- Surfactants

- Synthetic Fibers

- Thermal Oil

- Thin Liquids

- Thixotropic Fluids

- Toluene

- Ultra Pure Water

- Vegetable Oils

- Vinegar

- Viscose

- Viscous Liquids

- Wastewater

- Water

- Water Hardness

- Wine

- Wort

-

- Abrasion Resistant

- Adjustable-Flow

- Automatic

- Booster Sets

- Chemically Resistant

- CIP

- Close-Coupled

- Compact

- Containment

- Corrosion-Proof

- Direct-Drive

- Electric

- Explosion-Proof

- Fish Friendly

- Flange

- Heavy-Duty

- High System Pressure

- High Temperature

- High-Efficiency

- High-Flow

- High-Performance

- Horizontal Mount

- In-Line

- Intrinsically Safe

- Low Shear

- Low-Noise

- Mechanical

- Mechanical Seal

- Mixed Flow

- Mobile

- Modular

- Motorless

- Multi-Stage

- Non-Metal

- Oil-Free

- Pulse-less

- Rotary

- Rugged

- Sanitary

- Single-Stage

- SIP

- Solids Handling

- Variable Speed

- Vertical

- Vertical-Mount

How do scraped surface heat exchangers work?

Scraped surface heat exchangers, also known as scraped surface evaporators, operate based on the principle of forced convection and scraping. These heat exchangers consist of a cylindrical vessel with a rotating inner tube, called a rotor, that scrapes the surface of the heat transfer wall as it rotates. The rotor has blades that sweep the product from the wall and create a turbulent flow, which increases the heat transfer rate.

The product is fed into the vessel and is heated through contact with the heat transfer wall. As the product heats up, it becomes more viscous and tends to stick to the heat transfer surface. The rotating rotor prevents the product from sticking and creates a thin film on the heat transfer surface, which maximizes the surface area available for heat transfer.

The scraped surface heat exchanger is particularly useful for processing high viscosity products, such as sauces, pastes, and gels. The turbulent flow created by the rotating blades helps to break up any lumps or particles in the product, resulting in a smooth and homogeneous mixture.

Advantages and Benefits of Scraped Surface Heat Exchangers

Scraped surface heat exchangers (SSHEs) offer numerous advantages and benefits, making them a popular choice for various industrial applications. These include:

- Efficient heat transfer due to high turbulence and scraping action

- Suitable for highly viscous products that would otherwise foul traditional heat exchangers

- Minimizes product degradation and maintains product quality and integrity due to low shear and short residence time

- Versatile and customizable design to meet specific process requirements

- Easy to clean and maintain, reducing downtime and production costs

- High durability and long service life due to robust construction and materials

- Can be used for heating, cooling, crystallization, and other processes in various industries, such as food, chemical, pharmaceutical, and cosmetic

- Energy efficient and can reduce energy consumption and costs

- Can handle both continuous and batch processes

- Provides precise temperature control and uniform heat distribution

- Allows for high throughput and productivity due to fast heat transfer and short processing time

- Offers flexibility for future process modifications or expansions.

Industries and applications that uses scraped surface heat exchangers

Scraped surface heat exchangers are highly versatile and are widely used in various industries and applications for their numerous advantages. Some of the most common industries and applications where scraped surface heat exchangers are used include:

- Food Industry: Scraped surface heat exchangers are commonly used for processing food products that are highly viscous, such as peanut butter, fruit purees, sauces, confectionary, chocolate, and cheese curd. They are also used in the production of ice cream, yogurt, and other dairy products.

- Chemical Industry: Scraped surface heat exchangers are used for heating and cooling of chemicals in various processes, such as polymerization, crystallization, and condensation.

- Cosmetics Industry: Scraped surface heat exchangers are used for processing of various cosmetic products, such as creams, lotions, and hair gels.

- Pharmaceutical Industry: Scraped surface heat exchangers are used for heating and cooling of pharmaceutical products, such as ointments, creams, and lotions, during the manufacturing process.

- Pet Food Industry: Scraped surface heat exchangers are used for processing pet food products that are highly viscous, such as canned wet food and semi-moist products.

- Personal Care Industry: Scraped surface heat exchangers are used for processing various personal care products, such as soaps, shampoos, and body washes.

Important considerations when selecting scraped surface heat exchangers

When selecting a scraped surface heat exchanger there are several important considerations to keep in mind to make sure that the application is running smoothly. These considerations include:

- Viscosity: Scraped surface exchangers are designed to handle highly viscous materials, but it's important to ensure that the viscosity of your material is within the recommended range for the specific SSHE model you are considering.

- Particle Size: Depending on the application, the SSHE may need to be able to handle particulates or solid materials. It's important to ensure that the SSHE you select has the appropriate clearance and scraper design to handle these materials without causing damage.

- Temperature: The temperature of the product being processed is important to consider. Scraped surface exchangers can handle a wide range of temperatures, but it's important to ensure that the product are compatible with the SSHE's construction materials.

- Flow rate: The flow rate of the material being processed is another important consideration. SSHEs are designed to handle a wide range of flow rates, but it's important to ensure that the SSHE you select can handle the specific flow rate of your application.

- Cleaning: Scraped surface exchangers require regular cleaning to maintain their performance. It's important to consider the ease of cleaning when selecting an SSHE, as well as any special cleaning requirements or procedures.

Why buy scraped surface heat exchangers from AxFlow

AxFlow offers scraped surface exchangers for the widest range of industries and applications. Only at AxFlow do you receive individual advice from industry-experienced process engineers and the manufacturer-independent selection of the world's leading process technology. Do you need support in selecting the right pump for your needs? Do not hesitate to get in touch. AxFlows experts and engineers can provide guidance for selecting, specifying, installing, and maintaining your fluid handling equipment.