Challenges of Pumping Citric Acid

Citric acid, a weak organic acid naturally found in citrus fruits, presents unique challenges in fluid handling due to its chemical properties. Efficiently transferring citric acid demands careful consideration of materials, temperature, and specific gravity to ensure the safety and effectiveness of the pumping process.

Handling Citric Acid

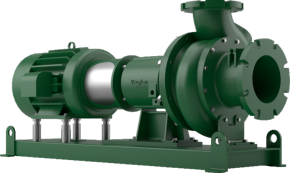

- Material Compatibility: Citric acid can corrode certain materials. Using pumps made of polypropylene or stainless steel is crucial to prevent corrosion and ensure longevity.

- Temperature Sensitivity: Citric acid properties vary with temperature. Pumps need to be equipped to handle the specific temperature range to prevent inefficiencies or damage.

- Specific Gravity Consideration: Citric acid solutions can vary in specific gravity. If the specific gravity exceeds 1.1, employing a trimmed impeller is essential to prevent motor overload.

Applications

Food and Beverage Industry: Used as a natural preservative and flavor enhancer in various food and beverage products, including soft drinks, candies, and canned fruits.

Pharmaceuticals: Citric acid is utilized in pharmaceutical formulations, acting as a stabilizing agent and a pH adjuster in medications.

Cosmetics: Found in cosmetics and personal care products, citric acid functions as a chelating agent, helping to preserve the product's quality.

Water Treatment: Employed in water treatment processes to adjust the pH levels and enhance the effectiveness of disinfectants.

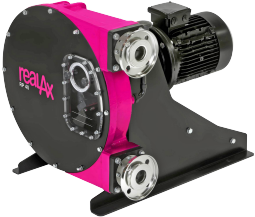

AxFlow offers specialized pumps designed to handle citric acid, ensuring the seamless transfer of this versatile organic compound in various industrial applications. Our expertise and range of pumps guarantee efficient and safe handling of citric acid and other challenging substances.