Challenges in Pumping Toxic Liquids

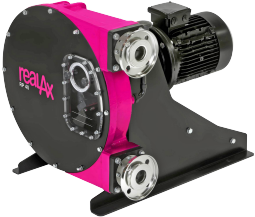

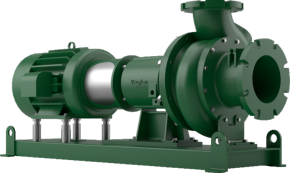

Pumping toxic liquids presents a unique set of challenges, requiring specialized solutions to ensure safety, containment, and efficiency. AxFlow, as a premier provider, offers a wide array of pumps tailored for handling dangerous and toxic media. The key lies in employing seal-less positive displacement and centrifugal pumps, eliminating the risk of leakage into the environment.

- Risk Mitigation: Prevention of leaks and spillage to protect the environment and personnel.

- Material Resistance: Pumps must resist a broad spectrum of chemicals, including acids, bases, and solvents.

- Safe Handling: Ensuring the safe dosing, bottling, pumping, and mixing of toxic liquids.

- Containment: Preventing toxic substances from escaping into the surroundings, especially during malfunctions.

Examples of Toxic Liquids

- Corrosive Acids: Hydrochloric Acid, Sulfuric Acid

- Biohazardous Materials: Laboratory Waste, Medical Waste

- Hazardous Chemicals: Cyanides, Mercury Compounds

- Radioactive Substances: Nuclear Industry Waste

- Toxic Solvents: Benzene, Toluene

Applications of Toxic Liquids

- Chemical Processing Plants: Handling corrosive chemicals for various industrial applications.

- Petrochemical Facilities: Managing hazardous materials in refining processes.

- Research & Development: Handling toxic substances in laboratory experiments.

- Waste Management: Safely containing and transporting hazardous waste.

- Environmental Cleanup Projects: Dealing with contaminated sites and substances.

AxFlow's expertise in providing pumps without mechanical seals ensures robust performance. Diaphragm constructions in positive displacement pumps and designs featuring magnetic couplings or encapsulated structures with wading rotors in centrifugal pumps are employed for enhanced safety and containment. With a focus on product integrity and environmental protection, AxFlow stands as a trusted partner in handling toxic fluids, offering innovative solutions for various industrial sectors.