Cryogenic liquids or fluids such as hydrogen, oxygen, nitrogen, argon and liquefied hydrocarbons like methane or natural gas, are not only cold but also thin with poor lubricating properties. There is usually very little NPSH availble due to the low SG of the liquids and the nature of their storage. Lastly, as liquied gases even the smallest break in the containment shall of the pump will result in them turning to gas and escaping.

Cryogenic liquids, which are substances with extremely low temperatures below -150 degrees Celsius, pose particular challenges when it comes to pumping due to their extreme cold temperatures and the potential for heat transfer that can cause them to vaporize.

Our UK and International team at AxFlow are experts in such fluids with over 30 years experience in the field.

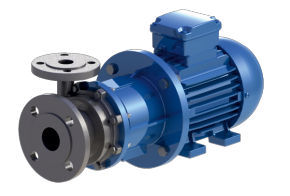

Mag drive & canned Cryogenic pumps

AxFlow offer a range of magnetic drive & canned pumps for pumping cryogenic liquids which offer several key benefits that are essential for handling such challenging fluids:

- Leak-free Operation: Magnetic drive Cryogenic pumps are hermetically sealed, which means there are no dynamic seals or mechanical shaft seals that can potentially leak cryogenic liquids. This feature ensures a leak-free operation, preventing hazardous and costly spills.

- Enhanced Safety: Cryogenic liquids, such as liquefied natural gas (LNG) or liquid nitrogen, operate at extremely low temperatures, which can cause conventional seals to become brittle and fail. Magnetic drive pumps eliminate the risk of seal failure, providing an added layer of safety in handling cryogenic fluids.

- Reduced Maintenance: Magnetic drive pumps have a simplified design with fewer moving parts, eliminating the need for seal maintenance and replacements, thus reducing downtime.

- Corrosion Resistance: Many cryogenic liquids, such as liquid oxygen or liquid hydrogen, can be highly reactive and corrosive to conventional pump materials. Magnetic drive pumps are often constructed with corrosion-resistant materials like stainless steel or specialized alloys, making them suitable for pumping these aggressive fluids.

Please see our Mag Drive & Canned Pumps catalogue...

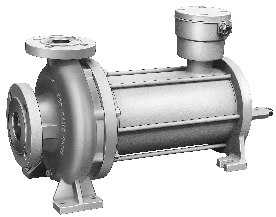

Axial Flow Cryogenic pumps

Why use our Axial flow cryogenic pumps...

- High Flow Rates: Axial flow pumps are known for their capability to handle high flow rates efficiently. In cryogenic applications, where large volumes of fluids need to be transferred, axial flow pumps excel in providing the required flow capacity while maintaining low energy consumption. This makes them ideal for pumping cryogenic liquids in bulk, such as in LNG terminals or industrial gas plants.

- Low NPSH Requirements: Cryogenic liquids, especially those at very low temperatures, can cause vaporization and cavitation in conventional pumps due to their low Net Positive Suction Head Required (NPSH). Axial flow pumps are designed with lower NPSH requirements, reducing the risk of cavitation and ensuring smooth and reliable operation when handling cryogenic liquids.

Complications when Pumping Cryogenic Liquids

Cavitation: Tends to occur when rapid changes in pressure cause the formation and collapse of vapor bubbles in a liquid, is a concern in cryogenic pumping. Proper design and operation are essential to minimize the risk of cavitation, which can lead to pump damage

Materials: Those used in cryogenic pump construction need to be carefully selected to withstand low temperatures. Stainless steels, aluminium, and specialized alloys are commonly employed to ensure mechanical strength and corrosion resistance.

Sealing systems: are critical in cryogenic pumps to prevent leakage and ensure the integrity of the system. Specialized seals and gaskets capable of maintaining flexibility and effectiveness at extremely low temperatures are employed. AxFlow offer the largest range of Sealless Mag Drive and Canned Pumps.