Pumping Tooth Paste

Coping with an abrasive sensitive and viscous product

Pump:

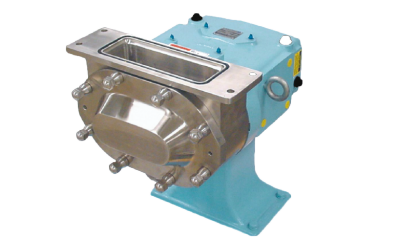

Waukesha Cherry-Burrell Brand – Model 064 Universal 2 Series

Industry:

Cosmetics Manufacturing

Problem:

Abrasive wear and pump limitations when handling a highly viscous tooth paste product

Solution:

The tooth paste manufacturing process requires the transfer of a highly viscous (>100,000 cps) product from processing tanks to a de-aerator. The customer was originally using progressive cavity (PC) pumps which required routine re-builds due to the wear caused by the abrasive paste.

Waukesha U2-064 pumps with single mechanical seals were selected to replace the PC pumps. The unique features of the pump's External Circumferential Piston ("ECP") style rotors provide long slip paths which gently scoop the solid particulates in the product. The tight tolerances of the U2 series prevent "slippage" back through the clearances of the pump, minimizing erosive wear. The pump also features a large rectangular inlet allowing the viscous product to more easily flow into the pump and prevent wear due to cavitation.

Selection of the Waukesha U2 pump reduced re-build time, maximized uptime, and minimize total cost of ownership.