Talk to me about Blackmer XLW

Thank you

Send a new messageWould you like to see other contact options?

Show me contact methods

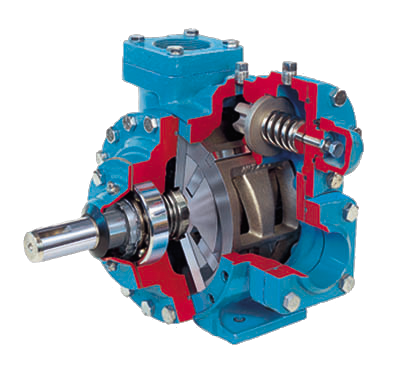

Blackmer XLW

Category: Pumps

SubCategory: RotaryVanePumps

Manufacturer: Blackmer

Industry:

SubCategory: RotaryVanePumps

Manufacturer: Blackmer

Industry:

For liquids with suspended abrasive particles flows to 43 m3/hr and pressures of 10 bar

Key specifications

- Flows up to 45 m³/h

- Pressure Up To 10.3 bar

FEATURES AND BENEFITS

- Replaceable casing liners and end discs that allow easy rebuilding of the pumping chamber to like-new condition without removing the pump from the piping.

- Hardened ductile iron construction with internal relief valve.

- Unique sliding-vane pump design self-adjusts for wear to maintain flow rates.

- Excellent self-priming and dry run capabilities.

- Blackmer mechanical seal and ball bearing construction provide maximum reliability

- Symmetrical bearing support assures even loading and wear for long life.

- Adjustable relief valve protects pump against excessive pressures.

- External ball bearings are isolated from pumpage by mechanical seals to maximize bearing life and minimize contamination risk.

- Easy maintenance: vanes can be easily replaced without removing the pump from the piping system.

Description

These pumps are widely used on vertical and horizontal bead mills, solvent recovery and oil patch applications including tank bottom recirculation, heat treater supply, enhanced oil recover, and crude or hot oil transfer.