Challenge of Abrasive Liquids

Abrasive liquids, characterized by the presence of solid particles, pose a significant challenge in various industrial applications. These demanding fluids, including Aluminium Oxide Slurry, Lime Dosing, Corrosive Dyes, and Crystalline Slurry, require specialized handling due to their abrasive nature. At AxFlow, we recognize the intricacies involved and offer tailored solutions designed to tackle these challenges effectively.

Handling Abrasive Liquids

- Utilizing Hard, Wear-Resistant Materials: Incorporating wear-resistant materials such as PE or chrome for internal components ensures durability and prolonged pump life, even in the harshest abrasive environments.

- Reducing Fluid Velocity: Employing pumps with a low shear and slow pumping action minimizes the velocity of the abrasive fluid in the pump chamber, mitigating wear and tear caused by high-speed movement.

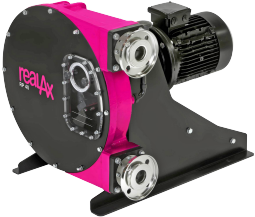

- Selecting the right equipment: Hose pumps, AODD pumps, and Progressive Cavity pumps, featuring tear-resistant properties, provide a soft yet robust solution. These pumps adapt to the abrasive particles, ensuring consistent performance over time.

Abrasive Liquids Applications

Aluminium oxide slurry plays a key role in polishing and grinding applications, where achieving optimal results depends on precise dosing. In water treatment, lime dosing is crucial for neutralizing acidic effluents, requiring pumps that are both accurate and reliable. In the textile and chemical industries, the use of corrosive dyes demands careful and precise dosing to ensure consistent coloring. Similarly, in semiconductor manufacturing, the flawless production process relies on the accurate delivery of crystalline slurries.

At AxFlow, we offer a comprehensive range of solutions tailored for abrasive liquids. Whether it's incorporating wear-resistant materials, controlling fluid velocity, or employing tear-resistant properties, we have the expertise and technology to meet your unique requirements.