Hygiene is paramount in prepared foods

Hygienic production requires understanding how the product behaves under differing conditions and recognizing the critical control points. But you also need to know how much the prepared food product in turn affects its environment. Bones, for example, can scour and abrade pipework. This can lead to the development of potential bacteria traps. And to complicate things further, carcasses from different animals behave in different ways.

Oil and fat - a hazard point

Oil and fat for secondary processes can have a tendency to accumulate inside surfaces. This accumulation affects temperature and consistency. In severe cases it can become a hazard point.

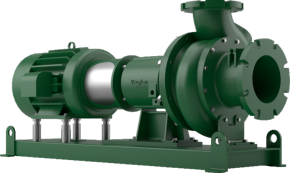

The end product is a high quality, and often low-fat delicate raw ingredient. But

the process itself is tough on equipment. Look for low, total lifecycle cost when deciding on equipment for prepared foods process equipment.

Prepared foods - challenges

These are volatile markets featuring multiple ingredients and fast changeovers pushing production flexibility to its limits. Prepared foods production requires ingenuity – and complete trust in your systems.

Minimizing prepared foods product wastage during cleaning and changeover is often overlooked. There’s no room for wastage in an efficient process.

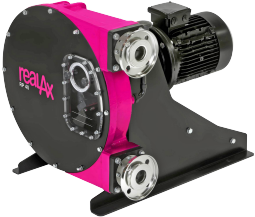

Flexibility in production starts with system design. Often complete skid systems

can be incorporated.

Low volumes can also mean bigger margins from niche products. Fast assembly of high value food products can even be achieved in a small floor space.

Extracting the full potential of your system means playing to its strength.