How to select peristaltic pumps

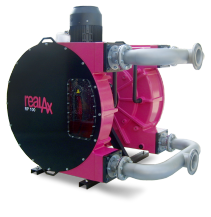

There are many important factors that should be considered when selecting a peristaltic pump.

THE CORRECT SIZING OF PERISTALTIC PUMPS

In addition to the size, the right selection of components determines efficiency, safety and service life. An even, constant flow rate is achieved by pulsation dampers. This protects the pipelines and all upstream and downstream components of the system. The restoring forces of the hose are supported with a vacuum device, so that the suction vacuum is created more quickly.

The important issues that need consideration when selecting peristaltic pumps are:

- Flow and pressure requirements.

- The liquid both in terms of it's compatability with tube and hose options and whether the use of a peristaltic pump is suitable.

- Liquid temperature as this would effect the tube and hose material choice.

- How many hours per day will the pump be required to run.

In general it's better to oversize a peristaltic pump as this will allow you to run it more slowly thereby increasing tube life.

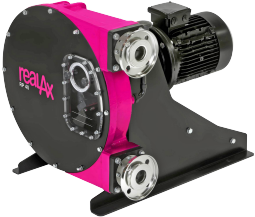

Shoes or Rollers?

Rollers

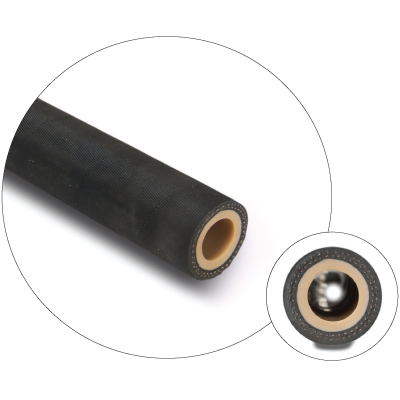

Mounted on bearings rollers compress the surface of the hose during rotation. This design generates less friction and can support pressures up to 8 bar.

Shoes

Fixed shoes are an option for RP models which move across the surface of the hose during compression. Shoes spread the pressure over a greater area and make a firmer seal than rollers. Typically they are preferred for higher operating pressures (up to 15 bar) and more viscous liquids.

|

|